Lens Grinding

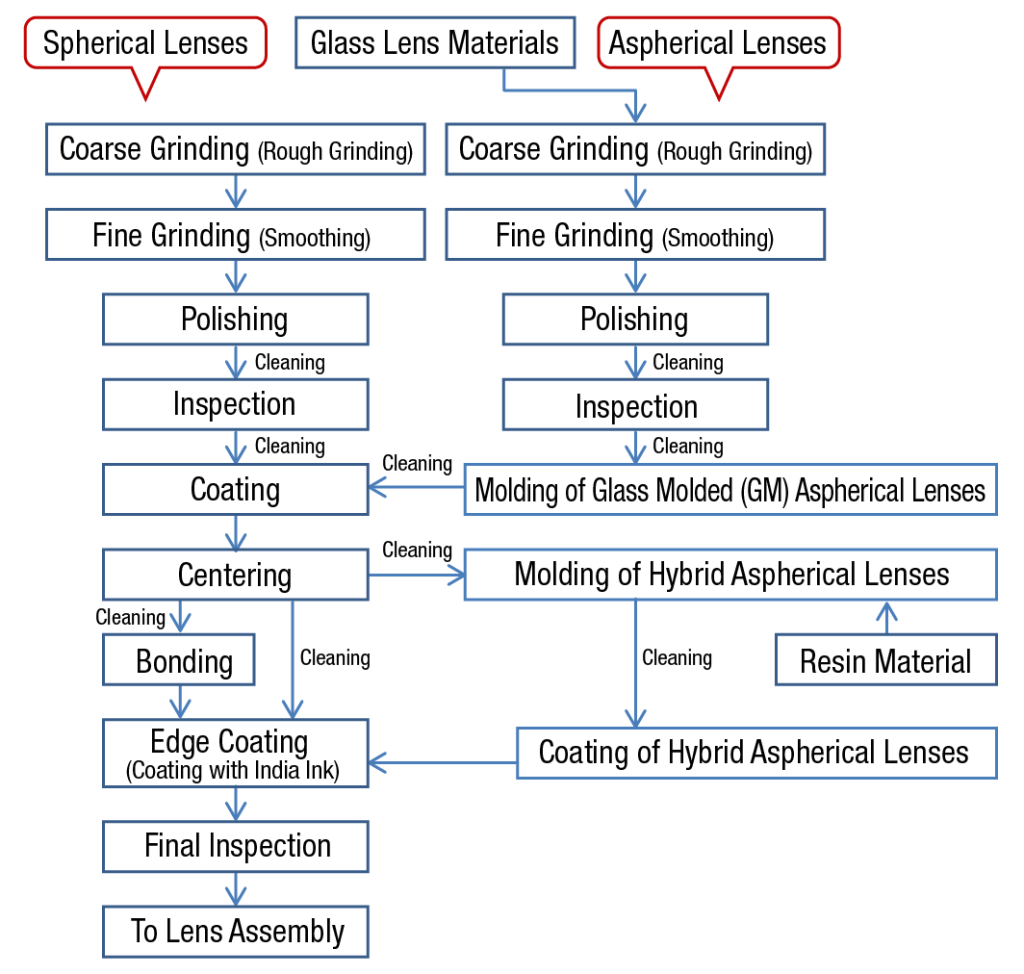

FORESEEN Lens Production Standard Process:

At FORESEEN OPTICS, we adhere to strict standards in our lens production process, ensuring that each lens delivers exceptional optical quality and reliability. Below is our standard lens production process, meticulously designed and optimized at every step, from raw materials to the final product, to provide the superior optical performance required for high-end rifle scopes and other optical devices.

1. Coarse Grinding

The production of lenses begins with the rough grinding stage. In this phase, we use coarse grinding tools to remove excess material from the lens blank, initially shaping it into the desired spherical or aspherical form. By utilizing the appropriate grinding equipment, we ensure that the lens curvature closely aligns with the design

Checkpoint: A preliminary inspection of the radius of curvature and surface quality is conducted to ensure that the lens meets the basic shape requirements after rough grinding.

2. Fine Grinding

During the fine grinding stage, we use fine grinding tools to further process the lens, reducing surface roughness and improving surface quality. This step is crucial to ensuring that the final lens achieves optical-grade precision.

Checkpoint: The surface roughness and thickness of the lens after fine grinding must meet the preset standards to facilitate the subsequent polishing process.

3. Polishing

After fine grinding, we move on to the polishing stage. High-precision polishing removes microscopic scratches from the lens surface, achieving the smoothness required for optical quality.

Checkpoint: The lens surface must undergo a thorough inspection after polishing to ensure it is free of scratches or microscopic defects, and that it meets the optical polishing standards.

4. Cleaning

After each processing step, we perform ultrasonic cleaning or use specialized cleaning solutions to ensure that the lens surface is free of any residues or contaminants. This step is crucial for maintaining the quality of the subsequent processes.

Checkpoint: Inspect the lens to ensure it is completely clean, free of water spots and residues, to guarantee the quality of the following coating process.

5. Coating

To enhance the optical performance of the lens, we apply an anti-reflective or protective coating to the lens surface. These coatings help reduce reflection and increase transmittance, thereby improving overall optical performance.

Checkpoint: Inspect the coating for uniformity, reflectance, and transmittance to ensure that each layer meets the designed performance requirements.

6. Centering

After coating, the lens undergoes a centering process to ensure that the optical axis aligns with the mechanical center. Precision machinery is used to adjust the lens position, optimizing its optical performance.

Checkpoint: Inspect the deviation between the optical axis and the mechanical center to ensure the lens centering meets design standards.

7. Bonding

For multi-lens assemblies, FORESEEN uses optical adhesive to precisely bond different lens elements together. The bonding process requires stable humidity and temperature conditions to ensure the quality of the adhesion.

Checkpoint: Inspect the bonding interface for any bubbles to ensure the integrity of the lens’s optical performance.

8. Edge Coating

Coating the edges of the lens (such as using Indian ink) can reduce the interference of stray light on the optical system and further improve the imaging effect of the lens.

Checkpoint: Confirm that the edge coating is uniform and free of peeling to ensure that the anti scattering performance of the lens achieves the expected effect.

9. Final Inspection

In the final inspection stage, we conduct comprehensive optical and mechanical testing on each lens. Using interferometers and other precision testing equipment, we ensure that every lens indicator meets customer requirements.

Checkpoint: Check the lens’s optical performance, including transmittance, reflectivity, and centrality, to ensure that the final product meets all design and customer specifications.

10. To Lens Assembly

After completing all quality control steps, the lenses finally enter the assembly phase. During this stage, the lenses are precisely installed into rifle scopes or other optical devices to ensure that the final product possesses exceptional optical performance and structure.

At FORESEEN OPTICS, every step of our lens production process is meticulously optimized and rigorously controlled to ensure that our products meet the highest optical standards. These standardized processes not only enhance production efficiency and material utilization but also guarantee the optical performance and quality of each lens. This enables us to provide high-quality customized optical solutions that meet the demands of the high-end market and professional users.