LPVO

LPVO (Low-Power Variable Optic) rifle scopes have become one of the fastest-growing categories in the optics industry over the past decade. With the widespread adoption of the AR15 platform, the demand for these optics, which combine the advantages of red dot sights and traditional rifle scopes, has seen significant growth. FORESEEN OPTICS, as a professional LPVO rifle scope manufacturer, we deeply understand the unique challenges of developing LPVO rifle scopes. In terms of optical design, our focus is on achieving a red dot-like view at low magnification (1x) while ensuring excellent image flatness and clarity at higher magnifications, meeting the needs of effective shooting at distances of 500 yards or beyond. This requires sophisticated design in both optical and mechanical engineering.

Structurally, LPVO scopes must strike the perfect balance between being lightweight and durable, requiring many design innovations that go beyond traditional approaches. After a decade of development, FORESEEN OPTICS has mastered the production of LPVO rifle scopes ranging from 1-4x to 1-12x, covering all the key segments of the market. We continue to explore new technologies to optimize costs and provide our brand clients with continuous product upgrades and a broader range of tactical equipment options.

It’s worth noting that LPVO rifle scopes have started to replace Trijicon ACOG scopes in some military applications, which will further drive demand in the market. If you aim to stay ahead of market trends, partnering with FORESEEN OPTICS to customize LPVO rifle scopes for your brand could be a wise strategic decision.

Provides a True 1x Performance Closely Red Dot Sight

Magnification Range up to 12x

Balanced Lightweight and Durable Design

Versatile Reticle Customization

FORESEEN LPVO Rifle Scope Series

| Picture | Product Code | Product Model | EXIT PUPIL Diameter (mm) | LENGTH (mm) | TUBE DIAMETER (mm) | EYE RELIEF(mm) | FIELD OF VIEW |

| HUQ1.25-4.5X26E SFP | 1.25-4.5X26E | 20.8-7.04 | 265 | 30 | 82 -78 | 14.2° -5.2° |

| TEF2-8X20 SFP | 2-8X20 SFP 3X28IR SFP | 10-2.5 | 185 | 25.4 | 89-76 | 3.8°-1.8° |

| ZHY1-4X24 SFP | 1-4X24 SFP | 20-5.8 | 249 | 30 | 91-89 | 9.15°-2.3° |

| WUX1-6X24 SFP | 1-6X24 SFP | 11-4 | 260 | 30 | 105-90 | 21° -3° |

| CHX1.2-6X24IR SFP | 1.2-6X24 SFP | 20-4 | 220 | 30 | 110-100 | 4.22°-1.1° |

| CHX1-8X24IR SFP | 1-6X24IR SFP 1-8X24IR SFP | 24-3 | 263 | 30 | 108-105 | 7° -2.1° |

| XIF1-10X24 FFP | 1-10X24 FFP | 24-2.4 | 245 | 30 | 94-89 | 22.84°-2.2° |

| CHX1-12X24IR SFP | 1-12X24R SFP | 24-2.5 | 292 | 30 | 127-125 | 20.8°-1.72° |

| SHM1-4×241 | 1-4×24 | 24-6 | 237 | 25.4 | 140 | 23.93°-6.06° |

| HUQ1-4X28E | 1-4×28 | 25.23-7.53 | 253 | 30 | 154.5-88.5 | 12°-4.6° |

| ZHY1-6X24SFP | 1-6X24SFP 1-6X24FFP | 8-3.5 | 268 | 30 | 91-89 | 10.97°-1.95° |

| WUX1-8x24IR | 1-8x24IR | 12-3 | 273 | 30 | 105-95 | 24°-3° |

| XIF1-8X24 | 1-8×24 | 10.5-3 | 270 | 30 | 100-90 | 22°-3° | |

| XIX1-5X24IR GT | 1-5X24 | 4.8 – 24 | 235 | 30 | 80 – 95 | 1.52°-0.38° |

| XIX4X30AO IR | 4X30 | 7 | 165 | 30 | 100 | 0.55° |

| XIX1-6X24IR PRO | 1-6X24IR | 4 – 24 | 220 | 30 | 135 | 3.5° – 21° |

| XIX4X30IR-A | 4X30 | 7.5 | 146 | 34 | 71 | 7.6° |

| XIX3X30IR PRO | 3X30 | 15.5 | 127 | 30 | 20 | 18° |

| XIX1.2-6X24IR-A | 1.2-6X24 | 4-20 | 240 | 30 | 50-150 | 7.96° |

| XIX1.2-6X24IR PRO | 1.2-6X24 | 3.38-16.9 | 230 | 30 | 86-105 | 3.2°-15.9° |

| XIX1-6X24IR | 1-6X24 | 4.6-15.5 | 220 | 30 | 98-136 | 4.8°-23.5° |

| XIX1-6X24 SFP | 1-6X24 | 4.6-15.5 | 220 | 30 | 98-136 | 4.8°-23.5° |

| XIF1-10×28 FFP | 1-8X24 1-10X28 | 10-3 | 275 | 34 | 102-98 | 22°-2.2° |

| BST1-8x24FFP | 1-8X24 | 10.5-3 | 270 | 34 | 102-88 | 25°-3° |

| BST1.5-5×20 | VCT1.5-5×20 | 13.4-4 | 220 | 25.4 | 100 | 16.2°-4.9° |

Choose from our base models and add custom features—we’ll redesign it to meet your needs.

Click the inquiry button and tell us what you’re looking for.

POPULAR SCOPES & SIGHTS FOR YOU

High-End LPVO Optical Design and Core Illumination Technologies

What an LPVO Is and Why It Matters

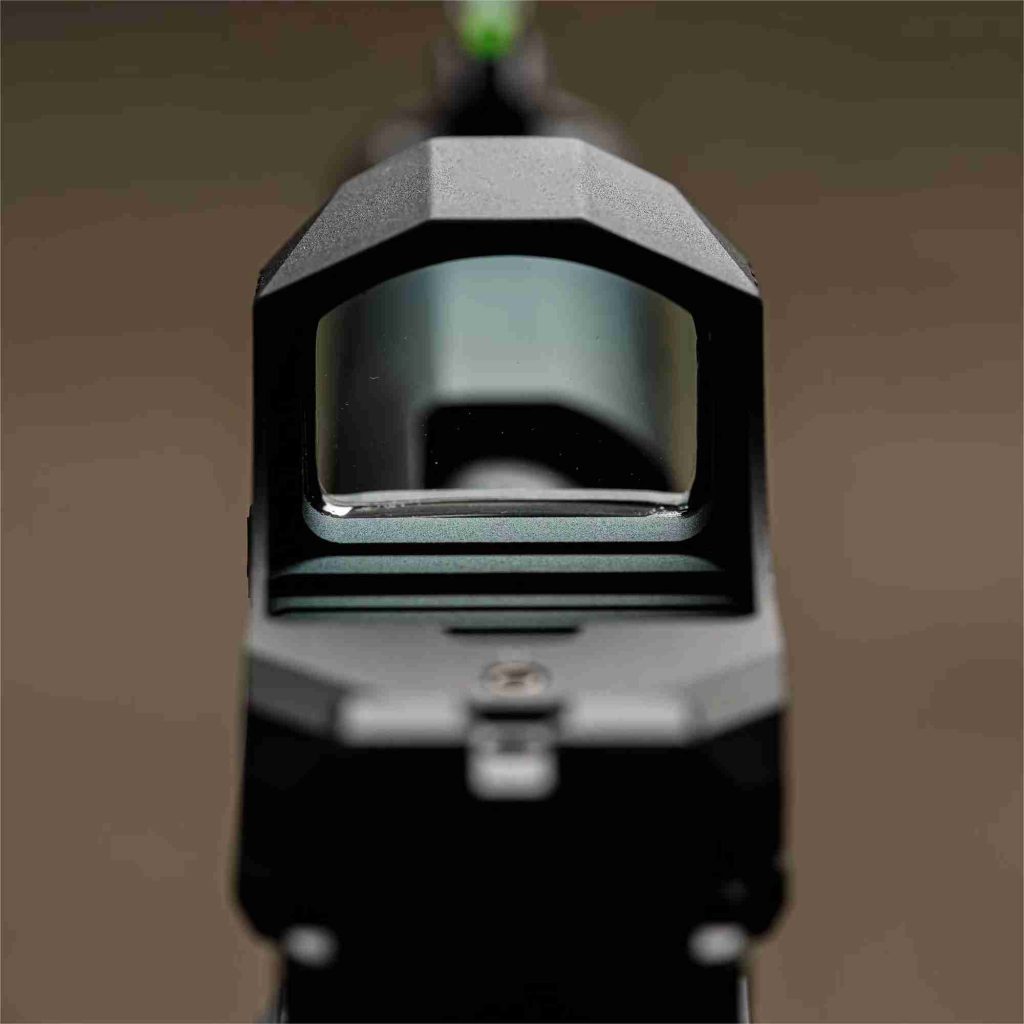

A Low Power Variable Optic (LPVO) is a rifle scope with a true or near-true 1× low end and a higher magnification such as 4×, 6×, 8×, or even 10×. At 1× it is expected to behave like a red-dot sight for fast, close-range engagements; at higher magnification it must provide enough detail and precision for medium-range shots. Because of this dual role, LPVOs have become a favorite in both tactical and hunting applications.

The core design philosophy of a premium LPVO is simple but demanding:

- At 1× it should look and feel almost identical to the naked eye—no distortion, no “tunnel” effect, and a forgiving eye box.

- At higher magnification it should offer clear, high-contrast images with precise aiming capability.

To get there, manufacturers must push both optical design and internal illumination technology: complex lens groups, high-grade glass, advanced coatings, and increasingly sophisticated reticle and illumination systems.

This article looks into the key optical design requirements for high-end LPVOs and the evolution of illumination technologies—from traditional LED-lit etched reticles to cutting-edge fiber-optic point systems. It also compares tactical and hunting LPVOs and how design trade-offs shift between these two major use cases.

Optical Design at 1×: True View and Distortion-Free Experience

“True 1×” performance is one of the most important benchmarks for an LPVO. A high-end LPVO at 1× should allow the shooter to keep both eyes open, with the image neither magnified nor reduced, and without obvious distortion or distracting parallax. To achieve this, the optical system must solve several challenges simultaneously.

1.Controlling Distortion and Fish-Eye Effect

Poor optical design often leads to edge distortion at 1×, similar to a “fish-eye” effect where objects near the edge are stretched or bent. This looks bad and, more importantly, can contribute to perceived parallax and point-of-aim/point-of-impact inconsistencies when the shooter’s eye moves off center.

Premium LPVOs mitigate this by:

- Using high-quality optical glass with carefully chosen refractive indices.

- Applying aspheric lens surfaces to control off-axis aberrations.

- Designing lens groups to minimize barrel or pincushion distortion at low magnification.

In practice, many experienced shooters find that well-designed 1–6× LPVOs hit a sweet spot: wide field of view, minimal fish-eye, and a very natural image at 1×. Once you push beyond 6× zoom ratio, it becomes increasingly difficult to keep distortion low at the low end without compromises elsewhere.

2. Wide Field of View and “No-Scope” Feeling

At 1×, an excellent LPVO should offer such a wide field of view (FOV) that the shooter almost forgets they are looking through a tube. The goal is to avoid a pronounced “looking through a pipe” or tunnel effect.

Design tools for achieving this include:

- Larger objective and especially larger ocular (eyepiece) lens diameters.

- Wide-angle optical layouts that allow a large apparent field of view.

- Eye relief and eye box tuned for fast, instinctive head placement.

In premium designs, eye relief typically ranges around 3–4 inches (about 7.5–10 cm), with a forgiving eye box that still presents a full, bright image even when the shooter’s head is slightly off-center. This is crucial for dynamic shooting—whether in competition, tactical use, or hunting moving game.

3. True 1.0× Magnification and Parallax Behavior

Ideally, the scope’s lowest setting is a true 1.0×. If the actual magnification is slightly above or below 1×, the brain will detect a size mismatch between the scope view and the unobstructed eye, which can slow target acquisition and feel “off” when both eyes are open.

High-end LPVOs therefore:

- Precisely calibrate lens spacing and curvature at the low end.

- Sometimes include dedicated compensation lens groups to nail the 1.0× value.

Most LPVOs use a fixed parallax setting (often 100 yards/meters). At 1×, however, targets are often much closer. A good design keeps residual parallax small enough that the shooter can treat the scope like a red dot—place the illuminated central reference on the target and press the trigger, without worrying about minor head movement.

4. Why 1× Is the Hardest Part of the Design

Ironically, 1× is often the most challenging point in the entire zoom range. The system has to deliver:

- Very wide field of view

- Very low distortion

- Minimal parallax error

- Comfortable eye relief and eye box

Optical designers typically use multi-element lens groups, fine-tune curvature, spacing, and glass types, and combine them with advanced multi-coatings. Some designs adopt “inverse fish-eye” or hybrid wide-angle configurations to gain FOV while canceling distortion.

The goal is straightforward: at 1× the shooter should feel like they are looking through a clean window—natural size, natural perspective, and no visual distractions.

Continuous Zoom: Managing Image Quality from 1× to Max Power

The defining value of an LPVO is its ability to transition seamlessly from 1× to higher magnification while maintaining a usable image. That requires careful optical and mechanical design across the entire zoom range.

1. High Resolution and Edge-to-Edge Clarity

At maximum magnification (6×, 8×, 10×, etc.), the LPVO must deliver enough resolution and contrast to identify and precisely hold on small targets at moderate distances.

Key design levers include:

- Objective diameter and aperture: Larger effective aperture improves resolution and low-light performance.

- Low-dispersion (ED) or fluorite-class glass: Controls chromatic aberration and cleans up color fringing, especially near the field edges.

- Field-flattening elements: Keep the image sharp from center to edge, even with relatively wide FOVs at higher magnification.

Although LPVOs don’t reach the 30×–50× range of dedicated long-range scopes, they still need to perform across a relatively wide field at higher powers. That is why many high-end models incorporate complex eyepiece designs with large image circles and well-controlled aberrations.

Mechanical alignment is equally important. The optical axis must be tightly aligned with the mechanical axis so that point of aim does not wander with magnification, and so that the reticle remains stable relative to the image.

2. Zoom Smoothness and Focus Stability (Parfocal Behavior)

Inside an LPVO, a zoom group and a compensation group move relative to one another to change magnification. A well-designed mechanism gives:

- Smooth, consistent zoom ring torque

- Predictable magnification changes

- Stable focus as magnification changes (parfocal behavior)

Ideally, once the shooter has set the diopter for their eye, the image remains sharp from 1× all the way up to the maximum power without the need to re-focus. That means the image plane must stay coincident with the eyepiece focal plane throughout the zoom travel.

Cheaper or rushed designs may show slight defocus at certain mid-range or high magnification settings, forcing the user to compromise on where the focus is “perfect.” Top-tier products invest a lot of effort in:

- Precisely shaped zoom cams and tracks

- Coupled moving lens groups that maintain a flat, stable focal plane

- Extensive prototyping and hand-tuning of the cam curve

Some LPVOs add a side-focus (parallax adjustment) turret to fine-tune focus and parallax at high magnification, but most omit this for size, weight, and simplicity. That puts even more pressure on the underlying optical and mechanical design to keep the image comfortably sharp across the zoom range.

3. Zoom Ratio and Design Trade-Offs

The modern LPVO trend is toward ever-higher zoom ratios: 1–4× used to be standard, then 1–6×, now 1–8× and 1–10× are widely discussed, with some even going beyond.

However, the higher the zoom ratio, the more difficult the design:

- The low end (1×) needs wide-angle, low-distortion optics with a forgiving eye box.

- The high end needs telephoto-like correction for aberrations over a smaller FOV.

Bridging these extremes in one compact scope tube tends to require more lenses, more moving groups, and more complex shapes. As a result:

Some 1–8× and 1–10× LPVOs feel less forgiving at 1× than classic 1–4× or 1–6× models.

Eye boxes can get tighter, and minor head movement can cause shadowing at the low end.

Designers may slightly compromise on true 1.0×, field of view, or distortion control to support a wider overall zoom range.

Compact high-zoom scopes (for example, certain 1–8× models known for tight eye boxes at 1×) are a direct consequence of squeezing a large zoom ratio into a small, lightweight package. By contrast, a larger and heavier 1–6× design often feels more forgiving and comfortable at the low end because the optical system is less stressed.

In practice, high-end LPVO designers decide early whether a given model will prioritize:

- Maximum versatility and zoom ratio, accepting some compromises at 1×, or

- Ultimate 1× speed and comfort, accepting a lower max magnification.

4. Mechanical Precision and Durability

Even the best optical design fails if the mechanics are sloppy. Premium LPVOs rely on:

- High-precision zoom cams and guide rails

- Tight tolerances on lens cell machining and alignment

- Robust erector tube assemblies that hold zero under recoil

- Careful sealing and purging (waterproofing and fog-proofing)

Top brands routinely perform multi-power inspection and hand adjustments during assembly. They may shim lens cells, fine-tune reticle position, and verify parallax and zoom tracking before the scope leaves the factory. This is one reason why high-end LPVOs are expensive: they contain both high-end optics and labor-intensive mechanical fitting.

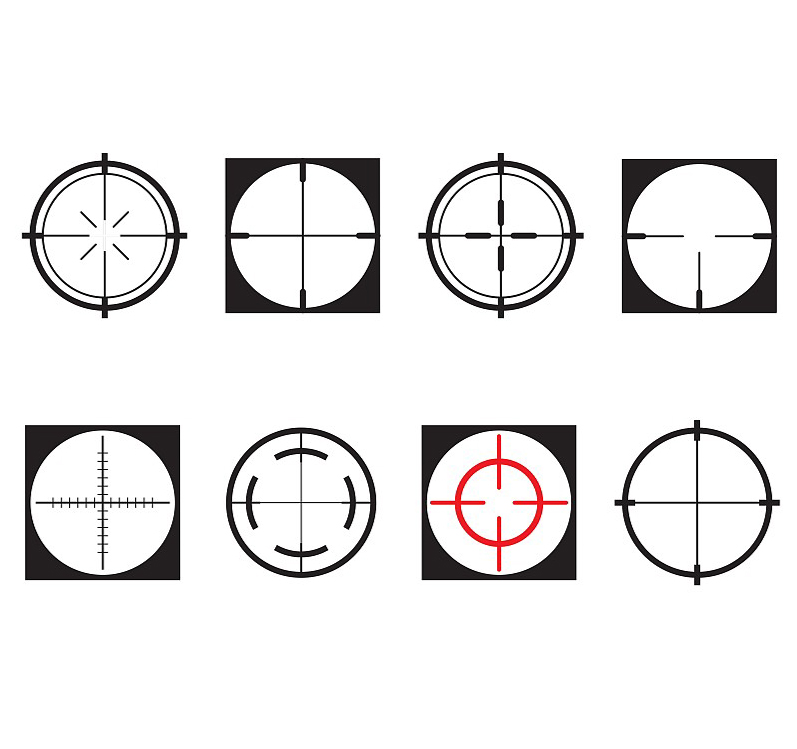

Reticle Design and Traditional Illumination

The reticle is the aiming “language” of the LPVO. In high-end scopes, traditional wire reticles have essentially disappeared and been replaced by etched glass reticles, which allow intricate patterns, high durability, and fine control over line weight.

1. Etched Reticles and Focal Plane Choices

Modern LPVO reticles fall into two broad families:

Tactical, Complex Reticles (Often FFP)

These are typically first focal plane (FFP) reticles with:

- MIL or MOA hash marks

- Ballistic drop compensation (BDC) scales

- Windage reference lines

- Ranging features and grids

Because FFP reticles scale with magnification, their sub-tensions remain accurate at any power. This is ideal for precision work at varying distances. The drawback is that at 1× the reticle shrinks dramatically; fine details may become tiny or almost invisible, making fast, instinctive close-range aiming more difficult unless the pattern includes bold outer elements such as thick bars or a large circle.

Simple, Fast Reticles (Mostly SFP)

These are typically second focal plane (SFP) designs and focus on:

- A bold center dot or small illuminated ring

- Simple crosshairs or a few basic holdover marks

- Clean, uncluttered field of view

In SFP scopes, the reticle appears the same size at all magnifications, so it remains easy to see and fast to use at 1×. The trade-off is that any holdover or ranging marks are only “correct” at a specific magnification (usually the maximum). Users must be aware of this and either stick to the calibrated power setting for precision shots or learn the approximate offsets.

2. Etching and Line Quality

High-end LPVO reticles are etched with photolithography and chemical etching processes on glass substrates. The typical process involves:

- Coating the glass with a photoresist and exposing the reticle pattern.

- Etching grooves into the glass where lines are needed.

- Filling the etched grooves with an opaque material (often black chrome or similar).

- Applying protective top coats.

Modern manufacturing can achieve line widths on the order of 10 microns or better. For LPVOs (maximum magnification generally under ~12×), line thickness requirements are less extreme than in 40×–50× competition scopes, where lines must be ultra-fine to avoid covering the target. That makes it easier to maintain consistent, clean lines even in mid-range price categories, which is why etched glass reticles have become standard across most LPVO tiers.

3. Traditional LED Illumination and Reflective/Fluorescent Coatings

To ensure the reticle remains visible in low light, most modern LPVOs provide illumination. The “classic” solution uses:

- A small LED module mounted in the scope body (often near the eyepiece or center).

- A light path, prism, or light pipe that directs LED output onto the reticle.

- Special reflective or fluorescent coatings applied only in selected reticle regions (often just the center).

When the LED is turned on:

- Only the coated parts of the reticle (for example, a central dot or horseshoe) light up strongly.

- The rest of the reticle remains dark or only mildly illuminated.

This approach solves older problems where turning on illumination would flood the entire field with light, causing glare and washing out the target. Modern illuminated etched reticles aim for:

- Even brightness along the illuminated elements

- Minimal halos and ghosting

- Controlled reflection, so that only the intended pattern glows

Most LPVOs only illuminate the central aiming feature rather than the entire reticle. This is because:

- In bright daylight, only a highly concentrated illuminated element will remain visible against high-contrast backgrounds.

- At night or in low light, fully illuminating a complex reticle can be distracting and may obscure fine target details.

High-end models pair efficient LEDs with well-engineered coatings and light paths to achieve “daylight-visible” illumination without excessive power consumption, usually with multiple brightness levels ranging from night-vision-compatible settings up to intense daylight modes.

However, this traditional LED + reflective coating system still has inefficiencies. A lot of light never reaches the eye and instead becomes stray light inside the scope, which can contribute to glare or reduce battery life. This is where fiber-optic illumination starts to shine.

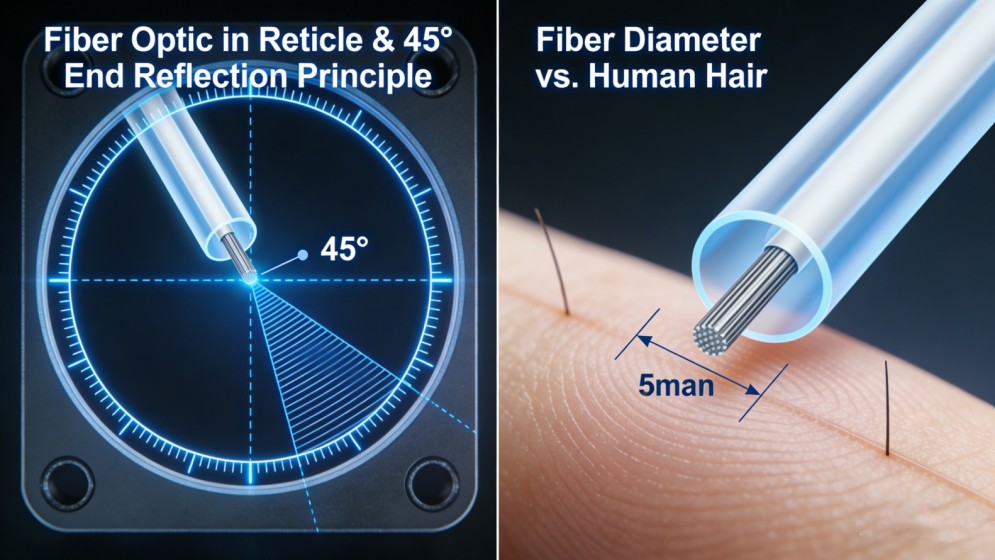

Fiber-Optic Illumination: Brighter, More Efficient Aiming Points

In recent years, fiber-optic illumination has emerged as a premium solution for LPVO aiming points. The idea is to borrow the “bright, concentrated dot” experience of a red-dot sight and integrate it inside a variable-power scope, while using the high efficiency of optical fibers to minimize power loss.

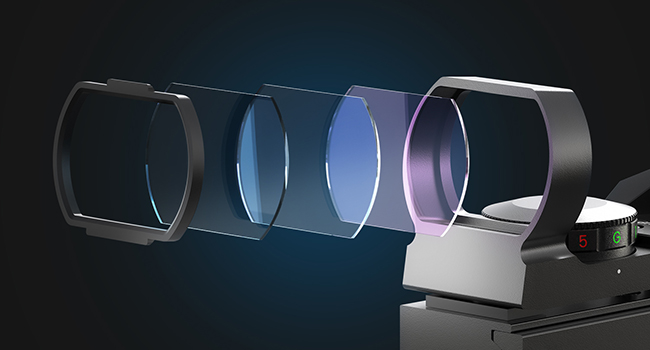

1. Basic Architecture: Fiber and 45° Reflection

A typical fiber-optic illuminated reticle uses:

- A very thin optical fiber embedded at the center of the reticle.

- One end of the fiber connected to a side-mounted LED light source.

- The opposite end cut and polished at approximately 45°, facing the shooter.

When the LED is activated, light travels down the fiber and exits at the 45° end, which reflects the light forward along the scope’s optical axis into the shooter’s eye. Because the fiber delivers light directly to that exit point, optical losses are minimal compared to the “flood and reflect” approach of traditional illuminated reticles.

The result is a highly concentrated, very bright dot in the center of the reticle.

2. Ultra-Fine Aiming Point

The fiber diameter determines the apparent size of the illuminated dot. Leading systems use fibers in the low-micron range. To put this in perspective:

- A fiber around 2–3 microns in diameter is roughly 1/40 the thickness of a human hair.

- At 100 meters, such a fiber can generate a dot on the order of about one MOA (or slightly above), small enough for precision yet still easily visible.

At high magnification the point remains tiny and refined, so it does not obscure small targets. At 1× the angular size is the same, which feels similar to using a small red dot sight—large enough for instinctive aiming, but not so large that it covers the entire target area.

Some European premium scopes are famous for this “extremely fine yet extremely bright” illuminated point, which is often considered ideal for both precise hunting shots and rapid target acquisition.

3. High Brightness with Low Power Consumption

The key advantage of fiber-optic illumination is efficiency:

- In a traditional system, the LED must emit a lot of light, much of which is wasted inside the scope body.

- In a fiber system, nearly all LED output is guided through the fiber to the aiming point.

Because of this high utilization, a fiber-optic dot can:

- Reach true daylight brightness that rivals or exceeds stand-alone red dots.

- Achieve that brightness at significantly lower LED power, extending battery life.

In practice, fiber-optic LPVOs can provide a very bright, crisp central dot in direct sunlight while still offering long runtimes—often measured in hundreds of hours even at higher settings. At low brightness, the dot can be dimmed to levels suitable for dusk, night use, or even under night-vision devices.

4. Optical Fundamentals: Total Internal Reflection and Side-Leakage Control

To achieve near-maximum light transmission and prevent distracting “red glow” in the field of view, the fiber itself must be carefully engineered.

Total Internal Reflection (TIR)

- An optical fiber consists of:A high-index core

- A lower-index cladding surrounding the core

When light enters the core within a suitable range of angles, it hits the core–cladding boundary at angles larger than the critical angle and undergoes total internal reflection. That means the light bounces repeatedly down the core with extremely low loss, even over relatively long paths.

In a premium LPVO implementation, the refractive index difference between core and cladding is tightly controlled so that:

- The acceptance angle is appropriate for the LED and coupling optics.

- Light remains well confined in the core until it reaches the exit end.

Side-Wall Light Suppression

If light leaks out of the sides of the fiber, it can create unwanted red streaks or diffuse glow in the image, especially in the reticle plane. To prevent this, high-end designs: Apply opaque or highly absorbing coatings to the fiber exterior (for example, black nano-coatings).

Use additional metallic or multi-layer structures around the fiber to block side-emitted light.

The goal is that the shooter only ever sees a single, concentrated point of light at the reticle center, with:

- No red smear along the fiber body

- No colored haze over the rest of the reticle

- A clean, high-contrast view of the target and reticle lines

When this is done well, the result is a pinpoint, razor-sharp red dot floating in a dark reticle structure, with the rest of the field remaining optically neutral and glare-free.

5. Manufacturing and Integration Challenges

Despite the performance advantages, fiber-optic illumination is hard to implement and drives cost:

- Fiber Material: The fiber must be extremely thin yet mechanically robust enough to withstand recoil, temperature extremes, and long-term use. Custom fibers and reinforcement strategies are often needed; standard telecom fibers are not optimized for firearm shock environments.

- Precision Cutting and Positioning: The 45° end must be polished to mirror quality and held at a very precise angle. Even slight deviations can distort the dot shape or misdirect the light. Positioning tolerances at the reticle center are on the order of the fiber diameter itself.

- Adhesives and Mounting: The fiber must be bonded in place with adhesives that do not creep, crack, or lose adhesion under thermal cycling and recoil.

- Optical Alignment: The emerging light cone must be aligned with the scope’s main optical axis so that the illuminated point coincides with the reticle intersection and remains parallax-free. Designers may add micro-lenses or adjust fiber length and placement to match the eyepiece optics.

- Visual Management of the Fiber Body: The fiber itself can appear as a small structure in the field of view. Typically it is placed near the focal plane so that, when the shooter focuses at target distance, the physical fiber blurs out and only the luminous point remains sharply perceived.

6. Current Limitation: Mostly SFP Applications

One important practical limitation is that fiber-optic points are currently most suitable for:

Simple, SFP reticles where the dot remains the same apparent size at all magnifications.

Putting a fiber-optic dot into an FFP reticle would cause the dot to change size with magnification, potentially making it:

- Too tiny to see at 1×

- Too large and coarse at max power

For that reason, you usually see fiber-optic illumination in:

- Hunting scopes that prioritize a clean view and a precise yet simple aiming mark

- Certain SFP tactical LPVOs that want red-dot-like speed at 1× with a crisp aiming point

Some flagship European hunting scopes and a few emerging designs from other manufacturers are good examples of this approach. The technology is gradually being adopted by more brands as the manufacturing know-how spreads and costs come down.

Tactical vs. Hunting LPVOs: Different Priorities, Different Trade-Offs

Although tactical and hunting LPVOs share the same basic architecture, their priorities differ. Understanding these differences is critical when choosing or designing a scope.

1. Tactical LPVOs: Speed, Durability, and Versatility

Tactical applications include military carbines, law-enforcement rifles, and competition setups such as 3-Gun or practical rifle matches. The typical requirements are:

- Fast close-range engagements: Wide, forgiving eye box and truly intuitive 1× performance.

- Daylight-bright central aiming reference: The center dot or small ring must be clearly visible in bright sunlight, enabling red-dot-like speed within close distances.

- Usable medium-range capability: Adequate precision and reticle features for hits at several hundred yards.

- Ruggedness: Resistance to shock, water, dust, and rough handling.

Design choices often seen in tactical LPVOs:

- Focal Plane: Many units aimed at general duty use are SFP, with a bold illuminated center element and perhaps a modest BDC that is accurate at a specific magnification. This preserves an easily visible reticle at 1×.

- Reticle Style: Hybrid patterns that offer a bright central dot or horseshoe for speed and some holdover marks for intermediate distances.

- Illumination: Emphasis on extremely high maximum brightness (“daylight visible”), sometimes pushing LED and illumination design to the limit. Fiber-optic points, where available, are an excellent fit because they combine high brightness with fine dots and good battery life.

- Mechanics and Ergonomics: Strong housings, reliable turrets, zoom rings compatible with throw levers, and mounting heights optimized for modern shooting postures (e.g., higher mounts for heads-up shooting around barricades).

For many tactical users, especially in real-world engagements where most shots occur inside 300 yards, the ability to “run it like a red dot” at 1× takes priority over maximum magnification or complex ranging grids.

2. Hunting LPVOs: Optical Quality, Low-Light Performance, and Carry Comfort

Hunting scenarios—especially driven hunts and close-range big-game hunting in forests or brush—are a natural fit for LPVOs. Here, priorities shift:

- Optical Clarity and Transmission: Many hunts occur at dawn or dusk, so high transmission, high contrast, and low flare are crucial. Premium hunting LPVOs often stress light transmission values above 90% and use sophisticated coatings to maximize low-light performance.

- Simple, Clean Reticles: Hunters generally prefer an uncluttered view, often with a simple crosshair and a central illuminated dot. The reticle must be immediately understandable and allow a fast, confident first shot.

- Fine but Bright Central Dot: A small illuminated point that can be set extremely bright for sunlight and extremely dim for last light is ideal. This is exactly where fiber-optic illuminated points shine: tiny, precise, and flexible in brightness.

- Weight and Size: Hunters may carry their rifle all day, so they are sensitive to the weight and bulk of the optic. Many hunting LPVOs aim for compact 1–4× or 1–5× ranges, which are more than enough for typical forest and short-to-medium-range shots while keeping the scope lighter and shorter.

Controls also need to be glove-friendly and intuitive, with clearly indexed illumination knobs and zoom rings that can be operated quickly but won’t move accidentally.

In summary:

- Tactical LPVOs bias toward robustness, speed, and multi-role capability.

- Hunting LPVOs bias toward optical excellence, low-light performance, and simplicity.

Both categories benefit from advances in lens design and illumination technology, but their tuning and feature sets diverge to match their users’ typical scenarios.

Integrated Innovation Driving the Future of LPVOs

High-end LPVOs sit at the intersection of advanced optical engineering and demanding real-world use cases. On the optical side, they solve the difficult problem of combining:

- A near-perfect, distortion-free 1× experience with a wide, forgiving eye box

- High-magnification clarity and resolution sufficient for precise shots at extended ranges

On the illumination side, they have evolved from:

- Non-illuminated or simple lamp solutions

- To LED-lit etched reticles with selective reflective coatings

- To today’s fiber-optic point systems offering ultra-fine, ultra-bright dots with low power consumption

Looking ahead, several trends are clear:

- Higher zoom ratios will continue to push designers to find new ways to balance 1× performance with high-magnification requirements.

- Improved coatings and glass will keep driving better light transmission, contrast, and aberration control, especially at 1×.

- More efficient LEDs, better batteries, and more refined fiber systems will make “always-ready” illumination with very long runtimes increasingly realistic.

- Gradual diffusion of fiber-optic technology from flagship models into mid-tier LPVOs is likely as manufacturing scales and know-how spreads.

There will also be new challenges: integrating advanced illumination with FFP reticles, guaranteeing fiber reliability under extreme conditions, and balancing feature sets against weight and cost. Yet the overall direction is clear: faster target acquisition, higher hit probability, and better performance across more scenarios.

For shooters and buyers, the key advice remains simple: choose what you truly need, not what others simply praise. Understanding the underlying optical and illumination technologies—true 1× behavior, zoom trade-offs, reticle architecture, and LED vs. fiber-optic illumination—helps you evaluate spec sheets and marketing claims and select an LPVO that genuinely supports your mission, whether that is tactical duty, competition, or hunting.

A well-designed, high-quality LPVO can effectively replace the traditional “red dot plus magnifier” setup, giving you one optic that covers close-quarters speed and medium-range precision in a single, integrated package.

FORESEEN One-stop Service,

Save Worry, Save Trouble, Save Cost

Stock Combination Delivery

Solution Matching

Development from Scratch

Quick Customization

Deep Customization

Choose us, and make your brand even greater

Blog

Continuous investment in technology and product upgrades is our primary means of helping

clients maintain their market competitiveness.