Reticle and Illumination

The Development History of FORESEEN Reticle Technology

The core technology of reticles lies in its ability to quickly align the aiming point with the target while resisting the recoil from firearms. Additionally, it must be easily recognizable under varying light conditions and backgrounds, all while minimizing target obstructions. Achieving this balance is challenging, which is why reticle technology has been a cornerstone of the FORESEEN OPTICS rifle scope manufacturing process. For over 30 years, we have been continually learning and advancing, striving to keep up with leading international technologies while also developing our own innovations.

Wire Reticle Era: International: Before the 1970s | FORESEEN: Before 1995

The earliest reticles used were fixed by intersecting wire strands, so this period can be called the Wire Reticle Era. All reticles at the time needed to be fixed at five points: four corners plus the center connection. You can see that the design of the original reticles adhered to this principle, which is why they are also referred to as crosshair reticles. These types of reticles could not be finely detailed, so they posed significant challenges in range estimation and FFP (First Focal Plane) design.

When FORESEEN first established its scope manufacturing factory, we could only source wire reticles from foreign suppliers. However, in 1995, we began producing our own metal wire reticles. Today, some of our cost-effective SFP scopes still widely use wire reticles due to their competitive cost and stability, making them well-suited for hunting-style SFP rifle scopes.

Printed Reticle Era: International: 1980s-1990s | FORESEEN: 1995-2005

In the 1980s, the scope industry began to introduce printed reticles. The appearance of printed glass reticles opened up new possibilities. Firstly, it broke free from the limitation of the traditional five-point fixation for reticle patterns, enabling the printing of any design on the surface of the glass reticle plate. During this period, many types of reticle designs were born. The challenge with printed reticles was that it decreased light transmission, and factors such as the flatness and alignment precision of the glass could affect the position and shape of the image. This had a negative impact on shooting clarity and accuracy. Despite the development of the glass industry, it wasn’t until the 1980s that printed glass reticles were applied to scopes.

FORESEEN OPTICS successfully began using printed glass reticles in rifle scopes and binoculars in 1995. However, within less than 10 years, as domestic industrial capabilities in China rapidly improved, we transitioned to etched reticle plates.

Etched Reticle Era: International: 1990-Present | FORESEEN: 2005-Present

In the 1990s, glass reticles evolved from printed designs to etched reticles, marking a significant upgrade. Etching involves multiple precise steps, including chemical etching of grooves, filling with black powder (usually black chrome), applying luminous coatings, bonding the protective flat plates, and cleaning. Each step must be carefully controlled, and this advancement is largely due to the development of precision optical processing techniques. As a result, etched reticle technology reached unprecedented levels of accuracy, durability, and contrast, which also paved the way for FFP (First Focal Plane) reticle designs.

FORESEEN OPTICS began manufacturing FFP rifle scopes in 2005. With guidance from international brand clients and support from domestic technology advancements, we successfully produced high-precision etched reticles. This marked the beginning of FORESEEN OPTICS’ development of high magnification rifle scopes with etched reticles.

Multifunctional Reticle Era: International: 2000-Present | FORESEEN: 2008-Present

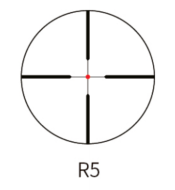

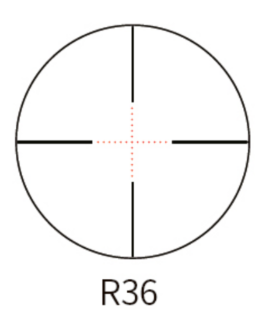

After the year 2000, the miniaturization and energy efficiency of LED lights made reticle illumination possible. This advancement allowed precision aiming in varying light conditions, leading to the development of new targeting methods. With compact spaces, we can even install LED lights in red, green, and blue, enabling seamless color switching based on different backgrounds for faster aiming.

Initially, illumination was simple, with full-screen lighting. However, the uniformity and brightness were less than ideal, and the lighting often interfered with target observation. Over time, new techniques were explored, such as applying special reflective coatings to specific areas of the reticle. This allowed for clear reticle patterns to remain visible even with low-power LED lighting. The illuminated areas could be the entire reticle or just a part, such as a circle or crosshair, depending on where the reflective coating was applied.

FORESEEN OPTICS has fully mastered this illumination technology, now successfully integrating it into various reticle systems.

In the past decade, rapid aiming with multifunctional and multi-scenario switching has become the direction of scope development. The rise of red dot sights also prompted the engineers at FORESEEN OPTICS to consider the application of single-point aiming in rifle scopes. Given the fundamentally different optical principles, we obviously cannot directly apply the imaging technologies of red dot sights or holographic sights to rifle scopes. Additionally, traditional methods of illuminating the reticle with LEDs do not provide a sufficiently bright red dot.

Thus, the latest optical fiber reflection technology has emerged. By using optical fibers, we can direct light into the center of the reticle with minimal light loss and secure it in place. Combined with precise 45° end-face grinding techniques, this process is complex but indeed effective. It allows us to create a near-perfect, high-brightness red dot with no glare effects. Furthermore, a smaller red dot is crucial for minimizing target obstruction, and our current technology achieves a red dot with a diameter of 3 microns, while Zeiss offers one at 2 microns.

How Reticle Illumination is Achieved?

Why Does the Reticle Need Illumination?

The reticle is a critical component inside a rifle scope, providing the shooter with a visual reference point to help quickly lock onto the target. In low-light environments, such as at dusk or night, or when aiming at dark bushes or foliage, the visibility of the reticle decreases, which can impact shooting accuracy. Therefore, the illumination of the reticle is essential to ensure that the shooter can clearly see the aiming point under various lighting conditions, avoiding missed targets.

Development History of Reticle Illumination Technology

- Early Attempts

In the early stages of scope development, some simple light source technologies were applied, including small halogen bulbs and natural light introduced through a window at the top of the reticle. However, halogen lamps were not suitable for long-term use due to their large size, heat production, high energy consumption, and short lifespan.

- The LED Era

In 1994, Zeiss introduced the LED illuminated reticle, and FORESEEN OPTICS has been closely monitoring the development of LED technology since the establishment of its factory. After 2005, with the miniaturization and cost reduction of LED technology in China, reticle illumination began to see mass adoption. At this stage, the reticle illumination was primarily based on monochromatic light sources, usually red or green, to improve contrast under different lighting conditions.

- Electronic-Controlled LED Era

As reticle illumination technology continued to evolve, scopes began incorporating electronic control systems with adjustable brightness levels and multiple color illumination. FORESEEN OPTICS leveraged China’s advantages in the electronics industry to design integrated circuits that allowed shooters to precisely adjust the LED brightness to suit different lighting conditions. Additionally, multi-color illumination was gradually implemented, enabling the use of different reticle colors for various shooting tasks, such as differentiating target types or shooting conditions. This design was especially popular in tactical scopes.

- Fiber Optic Illumination Era

The success of Trijicon’s fiber optic illumination led FORESEEN to explore the potential of this technology. Fiber optic illumination, which offers uniform brightness and does not require power consumption, further enhanced reticle illumination performance. Fiber optics can evenly distribute external environmental light across the illuminated area of the reticle and can automatically adjust the brightness based on external lighting conditions. This design eliminates the need for constant adjustments to the brightness knob during daytime use, making it ideal for switching between different lighting environments. Currently, FORESEEN’s fiber optic illumination technology is widely used in its own rifle scopes, prism scopes, and red dot sights.

- Single Fiber Reflection Technology

Whether LED or fiber optic illumination, both methods involve using a light source to illuminate reflective materials, which inevitably leads to some loss of brightness. FORESEEN OPTICS engineers are currently testing a new technology that uses fiber optics to direct light with minimal loss into the center of the reticle and secure it in place. This is complemented by a precise 45° end-face grinding process (at a 45° angle, light introduced by the fiber optic will be directed vertically into the eye from the center of the reticle, a complex but effective method). This approach allows for a nearly perfect, glare-free, high-brightness red dot. The size of the red dot is determined by the thickness of the fiber optic, and typically light-conducting fibers can be extremely fine (we currently use 3 microns, while Zeiss uses 2 microns), which is crucial for achieving minimal target obstruction.

Through the evolution of halogen lamps, LEDs, electronic control, and fiber optic technology, reticle illumination has not only enhanced shooting accuracy and efficiency but also significantly improved the shooter’s ability to perform in various environments. FORESEEN OPTICS will continue to explore innovation in this field and provide more intelligent solutions.

FORESEEN’s Classification and Overview of Reticles

There have been hundreds of reticle designs since their inception, and the product designers at FORESEEN OPTICS have classified them into three simple categories based on their experience. This classification helps new brand customers quickly select the type of reticle they need.

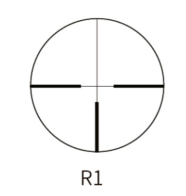

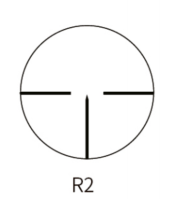

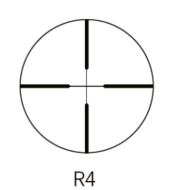

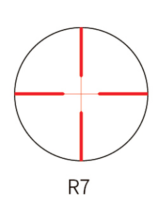

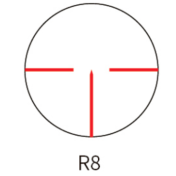

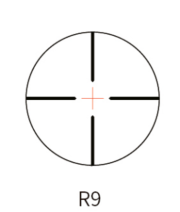

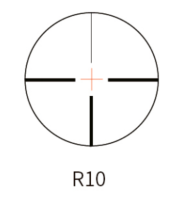

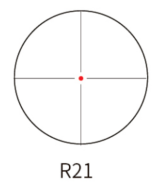

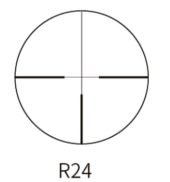

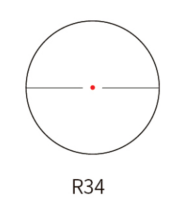

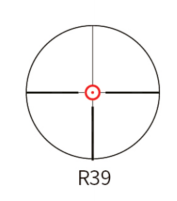

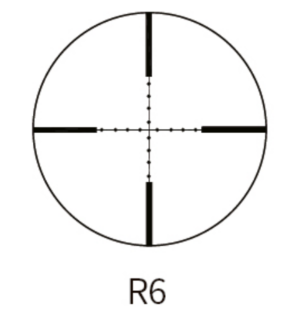

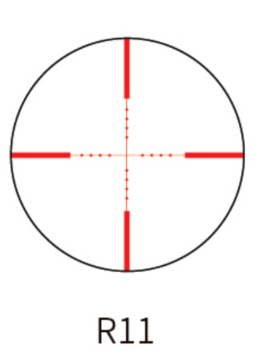

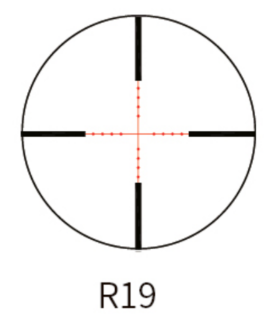

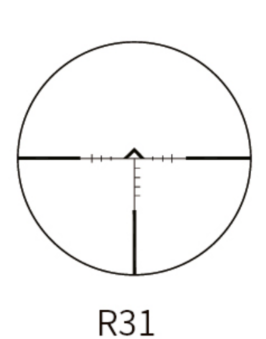

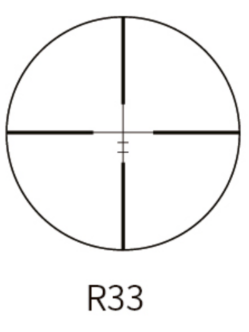

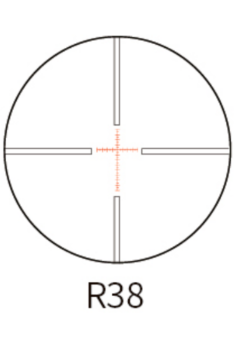

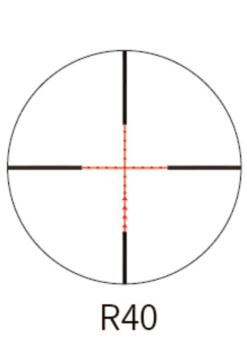

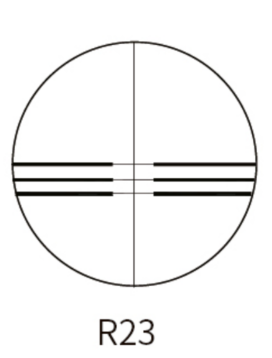

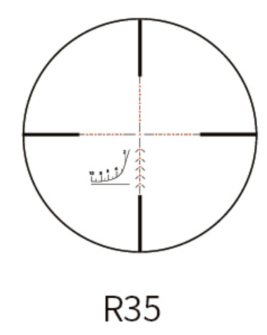

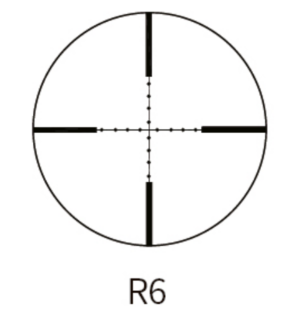

A: Basic Reticles (Simple Reticles)

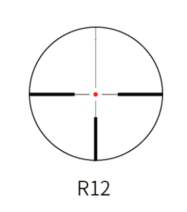

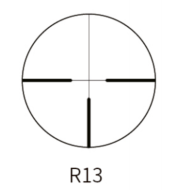

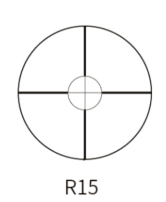

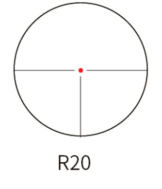

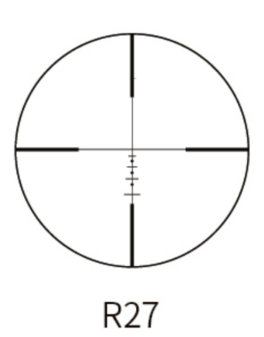

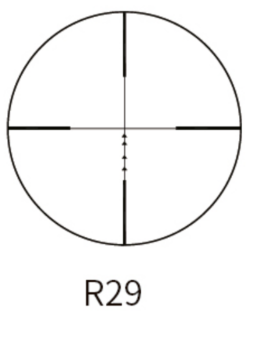

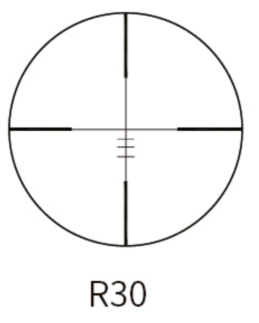

The characteristic of this type of reticle is that it only consists of a simple crosshair, without any ballistic compensation or range-finding indicators. It can be of uniform thickness, with a thicker edge and thinner center, or have a central aiming point, circle, or triangle symbol. It may also feature discontinuous lines, all designed to highlight the central aiming point. The red markings indicate designs that can be illuminated independently. These types of reticles are usually easier to manufacture, as they do not require the precise distance etching of BDC (Ballistic Drop Compensation) reticles or the more intricate design required for range-finding reticles. Such reticles are often used in SFP (Second Focal Plane) designs and are typically made with wire reticles to reduce costs.

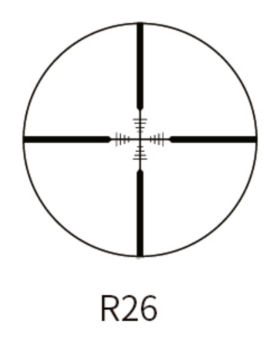

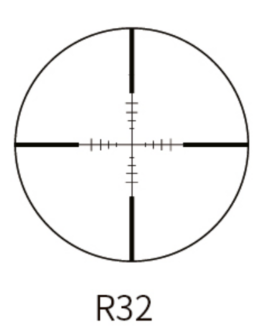

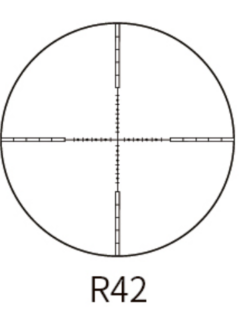

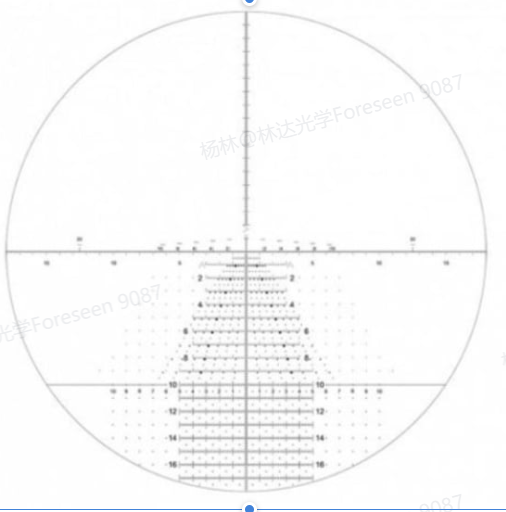

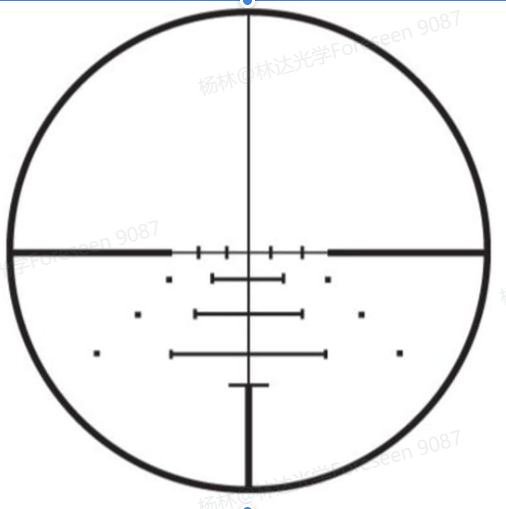

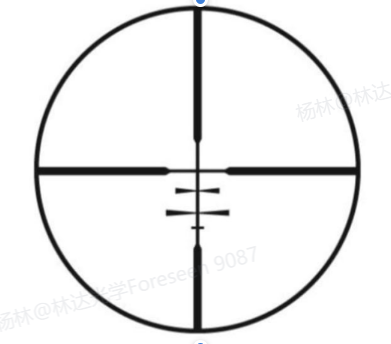

B: Ballistic Drop Compensation (BDC) Reticles

The characteristic of this type of reticle is that it includes vertical point or line graduations to enable distance measurement without the need for adjusting the ballistic compensation turret (i.e., no need to calculate and adjust the click values). Special attention must be paid during the manufacturing process to ensure the precise distance of each ballistic compensation point to avoid shooting errors, as this could cause the entire rifle scope to lose its BDC functionality. Complex BDC reticles are typically used for long-range precision shooting and are designed and manufactured to work in conjunction with FFP (First Focal Plane) systems.

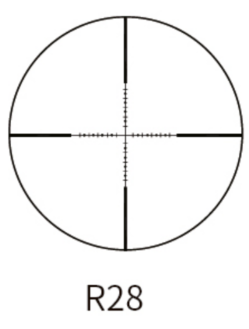

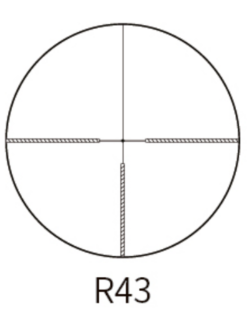

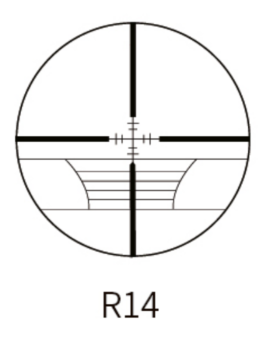

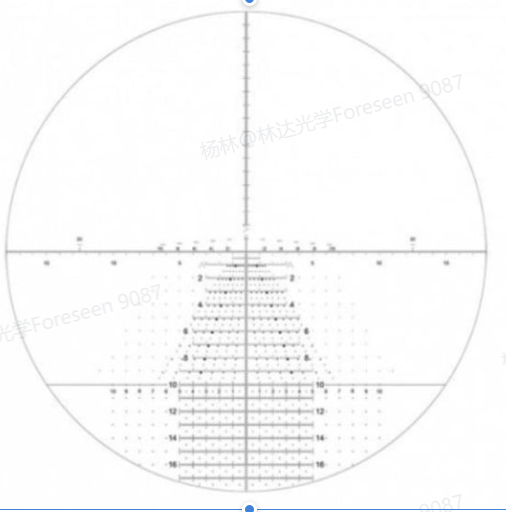

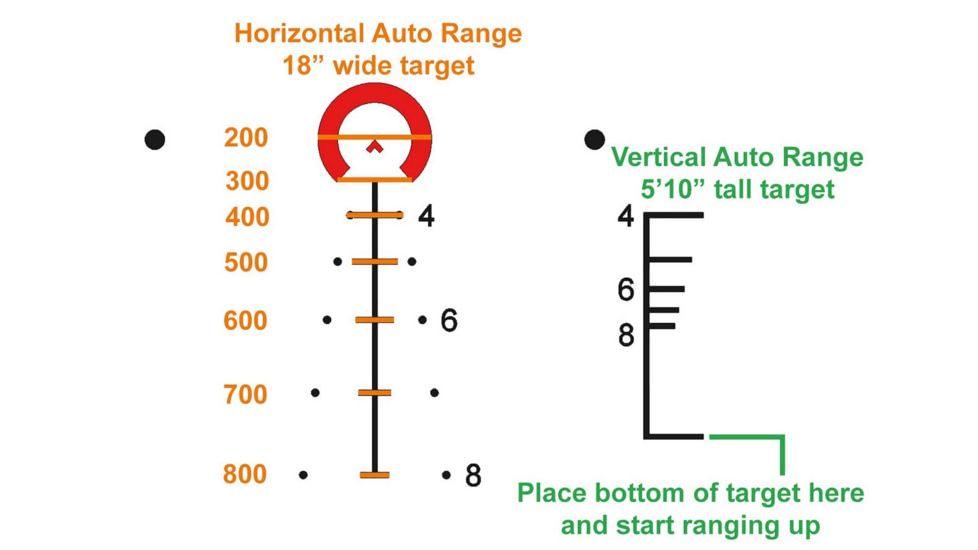

C: Rangefinding Reticles

This type of reticle is designed to assist the user in determining the distance between the shooter and the target. The typical targets are human figures, although some hunting-specific brands design reticles tailored for measuring different animals (e.g., wild boar). Many of these rangefinding reticles feature graduations at the lower part of the reticle image. Some include horizontal lines of varying width and height below the crosshair to estimate the target’s distance based on either length or width. Rangefinding reticles are usually equipped with BDC functionality. The following two examples are based on using a person’s width or height for distance estimation. Therefore, this type of reticle is typically used by military and law enforcement clientele.