Cost Control

| Cost Control Begins at Rifle Scope Design

At FORESEEN OPTICS, cost control begins with rifle scope design. By integrating cost optimization from the early stages of development, our design process takes into account material usage, manufacturing processes, and component quantity optimization. Our design engineers prioritize components and structural solutions that align with cost control objectives, aiming to minimize manufacturing and assembly costs while meeting customer requirements.

1. Customer Needs Analysis and Recommendations

In the initial design phase, FORESEEN OPTICS works closely with customers to ensure the design meets core needs without adding unnecessary costs.

Understanding Customer Usage Scenarios

We conduct in-depth discussions to understand the specific usage scenarios of our rifle scopes. By understanding the environment and application, we can identify which auxiliary features are truly necessary.

- Minimizing Unnecessary Features: We typically advise against adding features that cater to extremely niche use cases, as these can increase costs without providing significant value.

- Balancing Rifle Scope Attributes: Depending on the usage scenario, we prioritize and balance various aspects of the rifle scope, such as durability, accuracy, clarity, portability, and visual aesthetics, ensuring that the most critical needs are met while avoiding overdesign.

2. System Selection

FORESEEN OPTICS prioritizes the use of mature systems to save on research and development costs and time.

Selecting the Optimal System

During rifle scope design, we choose from optical systems, adjustment mechanisms, illumination systems, reticle components, and structural elements. Using mature solutions for adaptation and fine-tuning helps reduce R&D time and cost. This approach also provides better lead times, more competitive pricing, and greater stability in component quality. Our extensive library of over 500 rifle scope solutions allows for rapid adaptation and flexible design choices.

3. Process Design

Optimized process design directly impacts production efficiency, rifle scope quality, and cost control.

Efficient Production Processes

Well-designed processes can increase production speed, improve yield, and enhance material efficiency. For instance, optimizing the cutting path during the rough shaping of optical lenses helps minimize material waste. Similarly, careful selection of aluminum alloy bar sizes for CNC machining reduces scrap and improves overall material utilization. FORESEEN OPTICS continuously refines its process flows to reduce material and production costs while maintaining high rifle scope quality.

4. Equipment Selection

Choosing the right equipment is a crucial step in reducing manufacturing costs.

Flexible Use of Machinery

Not all rifle scope components require multi-axis CNC machining centers for full integration. Depending on rifle scope requirements, FORESEEN OPTICS selects appropriate machining methods, effectively utilizing labor costs and different types of machinery to reduce manufacturing expenses. For example, using simpler equipment for straightforward parts can save 5%-15% of total cost. Additionally, a smart combination of automated and manual processes allows us to maintain quality while achieving cost efficiency.

5. Centralized Procurement and Standardized Storage

Centralized procurement helps control costs and efficiently manage the supply chain.

Effective Supply Chain Management

FORESEEN OPTICS leverages an advanced supply chain management system to procure materials in a centralized manner: 30-day quantities of packaging materials, 60-day quantities of components, 90-day quantities of aluminum, and 120-day quantities of optical materials. This approach lowers raw material costs and mitigates risks associated with price fluctuations. Proper inventory management ensures smooth rifle scope production, avoiding idle capacity due to material shortages or delays.

6. Process Operations and Transition Guidelines

Efficient process transition management is key to maintaining rifle scope production stability.

Optimizing Process Transitions

FORESEEN OPTICS has found that maintaining a single operational mode for each piece of equipment and assembly process ensures maximum efficiency. However, uneven order distribution and delivery time differences often require adjustments. To facilitate these transitions, we use detailed process operation cards that guide each rifle scope production transition, ensuring minimal disruption. Optimizing scheduling and transition processes helps increase initial production yield and maintain high efficiency—key capabilities honed through our 30 years of mass production experience.

Through these comprehensive design and process control strategies, FORESEEN OPTICS integrates cost control into every step of rifle scope design, effectively reducing manufacturing costs and increasing efficiency during subsequent production phases.

| How FORESEEN OPTICS Improves Material Utilization: Key Cost Control Measures in Rifle Scope Component Machining

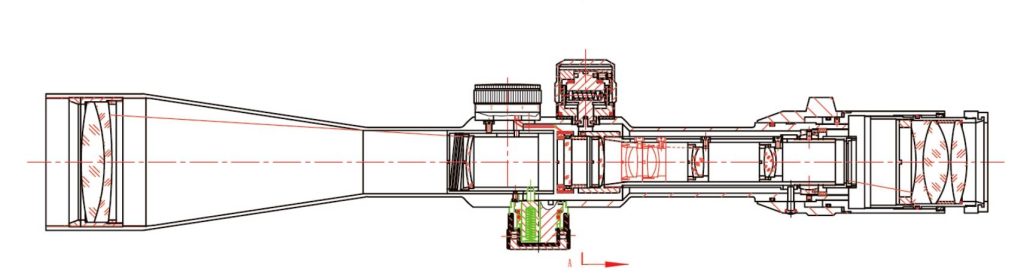

Precision machining is like a sculptor carving a beautiful piece of jade—our goal is to retain as much of the jade in the final product as possible, rather than turning it into waste. This is the shared direction of our machining and structural design efforts. In the manufacturing of rifle scopes, FORESEEN OPTICS optimizes part geometry, selects appropriate materials, and arranges machining processes to maximize material utilization and production efficiency. Below, we detail our strategies in rifle scope production from three key aspects: geometry optimization, material selection, and process adjustment.

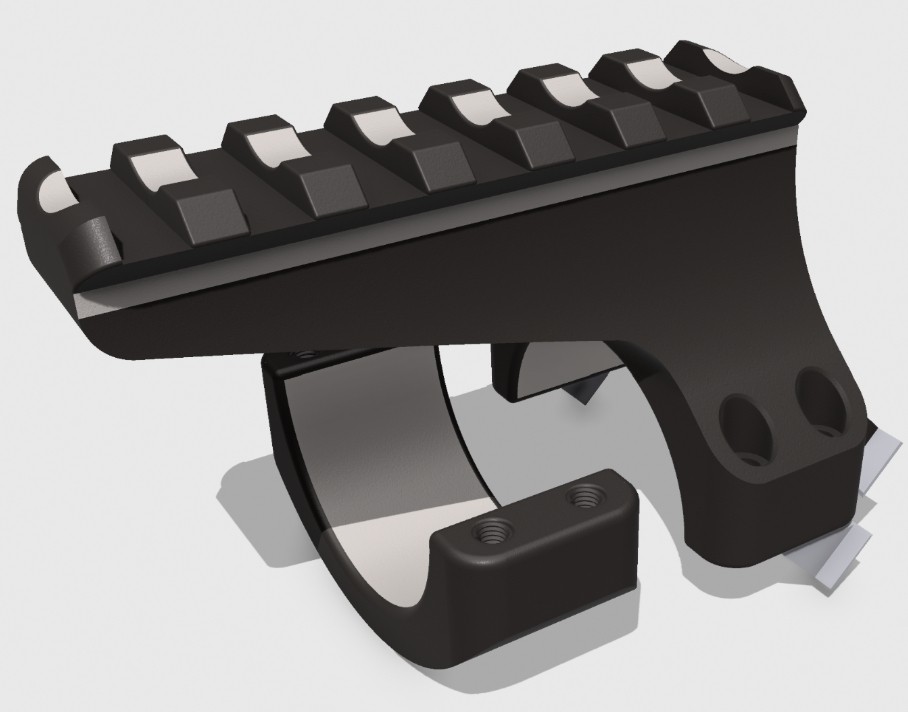

- Geometry Optimization

FORESEEN OPTICS optimizes the geometry of rifle scope components during machining to increase material utilization. We balance the functional requirements of each rifle scope part with the material removal needed, reducing unnecessary cavity cutting while maintaining the strength and stability of the components.

Equipment Utilization and Cavity Optimization: For different geometries, we choose the most suitable equipment for rifle scope part machining. For parts that require significant hollowing, we use multi-axis machining centers to achieve complex shapes in as few steps as possible. For simpler cavity shapes, we use more economical equipment to reduce machining time and costs.

Collaboration in Structural Design: During the design phase of rifle scopes, our engineers work closely with the machining team to ensure the part geometry is optimized for material conservation during processing, and to avoid unnecessary complexity that could increase material removal.

- Aluminum Bar/Tube Material Selection

In material selection, FORESEEN OPTICS pays careful attention to the choice between aluminum bars and tubes for rifle scopes to ensure the best balance of material utilization and cost-effectiveness.

Bar vs. Tube Selection: Depending on the specific shape and functional requirements of rifle scope parts, we choose either aluminum bars or tubes. For parts with thin walls and significant hollow structures, tubes are preferred to minimize material removal. For components requiring higher structural strength, bars are selected, but their diameter is optimized to minimize unnecessary material removal during machining.

Reducing Material Removal: When selecting material specifications, we aim for dimensions that are close to the finished rifle scope component size, minimizing unnecessary cutting and scrap. This approach reduces material waste and machining time, ultimately lowering overall costs while maintaining the quality of the rifle scope.

- Process Adjustment

Process adjustment is key to achieving efficient machining and reducing the production cost of rifle scopes. FORESEEN OPTICS optimizes the sequence of turning and milling operations to ensure each step achieves the most efficient material removal and best surface quality.

Order of Operations: Turning vs. Milling

In the machining of rifle scope parts, we determine whether to turn or mill first based on the characteristics of each component. For parts requiring precise external profiles, turning is often performed first to create the base shape, followed by milling to handle more complex details, ensuring accuracy and minimizing the risk of re-positioning errors. For flat structures requiring extensive milling, milling is prioritized to quickly remove excess material.

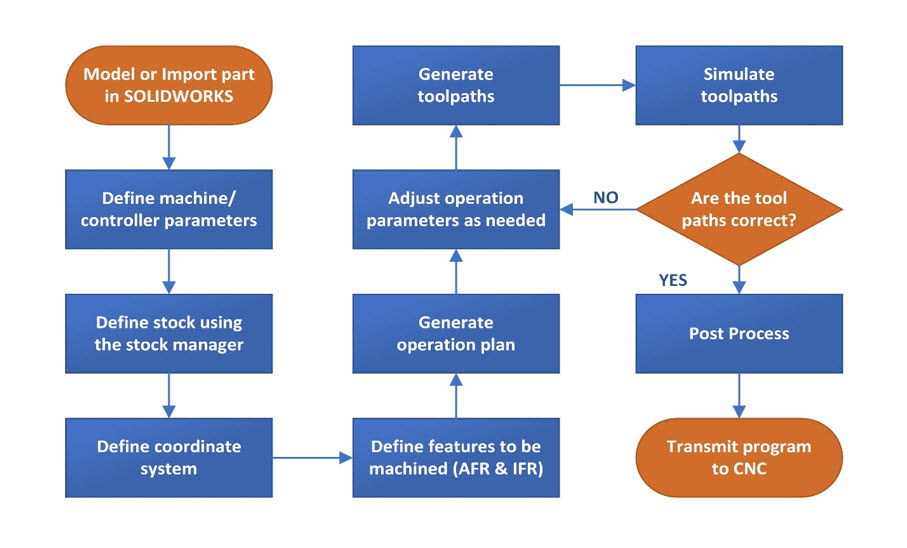

Machining Path and Strategy Adjustment: Using advanced programming software, we meticulously plan the machining path for rifle scope parts, reducing non-productive tool movements and shortening tool paths to decrease machining time. Additionally, by using specialized fixtures during process transitions, we minimize the time needed for re-clamping and re-positioning, thus improving the efficiency of rifle scope machining.

Through these measures, FORESEEN OPTICS ensures that each piece of material used in rifle scope production is maximized, while also reducing machining time and waste. This detailed approach to machining and structural design not only boosts the production efficiency of our rifle scopes but also helps us produce high-quality products at a lower cost.

| How FORESEEN OPTICS Selects Machining Equipment for Rifle Scopes

At FORESEEN OPTICS, we understand that not all rifle scope components require the same level of machining complexity. By selecting appropriate equipment for each component based on its specific requirements, we can effectively control manufacturing costs while maintaining quality. Our flexible approach includes the use of manual lathes, automatic lathes, and CNC machining centers, chosen based on the precision and complexity of the parts. Additionally, for components that can be standardized, we conduct centralized external procurement to further reduce costs.

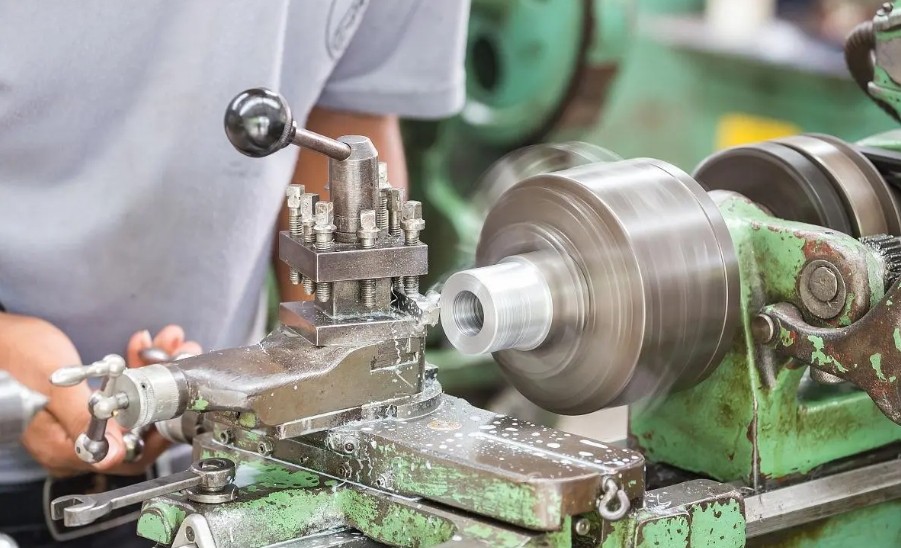

- Manual Lathe Machining

For very simple components with low precision requirements, we use manual lathes. These parts usually involve straightforward machining operations. Manual lathes are suitable for maintaining a long-term, single-operation process, reducing operator intervention, and making production more cost-effective.

- Automatic Lathe Machining

Most rifle scope components are produced using automatic lathes, including turning, milling, and boring operations. These machines are well-maintained to ensure consistent precision, making them suitable for parts with moderate complexity, such as basic rifle scope bodies and caps. However, automatic lathes often require multiple steps to complete part production, involving removal, re-clamping, and repositioning, which can lead to cumulative tolerances. Therefore, automatic lathes are suitable for general component production but are not ideal for high-end or complex components.

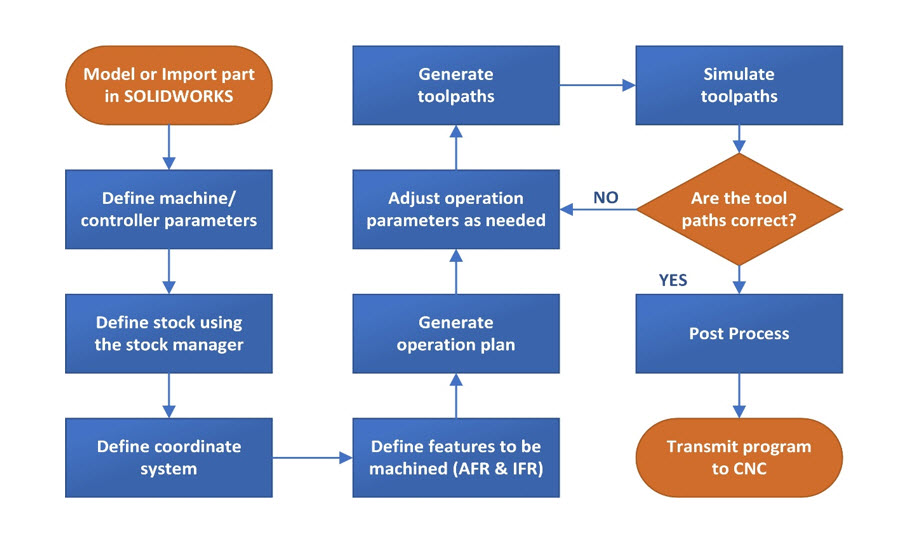

- CNC Machining

For components requiring high precision and complex machining, we use CNC (Computer Numerical Control) machining centers. FORESEEN OPTICS has over 30 advanced multi-axis CNC machines (including 4, 5, and 6-axis machines) that meet a variety of precision and customization needs.

CNC machining centers offer the following key advantages:

- Multi-functionality: CNC centers can perform milling, drilling, tapping, and boring, all controlled by multiple axes, allowing for multiple operations in a single setup.

- High Precision: The computer-controlled precision ensures consistency and high accuracy, which is crucial for the quality of rifle scope components.

- High Level of Automation: The automatic tool-changing system (ATC) allows multiple operations to be completed on a single workpiece without manual intervention, improving efficiency and reducing labor costs.

- Programming Control: The ability to program machining paths allows us to handle complex shapes with ease, ensuring that components meet high standards.

- Flexibility: CNC machining is suitable for small-batch, high-variety production, making it ideal for customized rifle scope components.

- Cost Considerations: Despite the high cost of CNC equipment and maintenance, CNC machining is the ideal choice for high-value precision components. Where possible, we choose lower-axis CNC machines to keep costs down while meeting product requirements.

- Centralized Procurement of Standard Components

For components in rifle scope production that can be standardized, FORESEEN OPTICS prefers centralized external procurement. Outsourcing these standard components not only helps reduce production costs but also ensures consistency and stability of supply. This approach significantly shortens production cycles and reduces additional costs associated with custom component machining, making the overall production process more economical and efficient.

Balancing Equipment Selection and Cost Management

At FORESEEN OPTICS, we work closely with our customers to determine the most suitable machining approach for each rifle scope component, balancing performance and cost. Based on the complexity of the component design, we aim to use the most appropriate CNC equipment. For components where shape complexity does not affect product precision, we prioritize the use of lower-axis CNC machining centers to significantly reduce costs while maintaining product innovation.

In addition to CNC machining, the production of rifle scope components requires three other key machining steps, depending on specific requirements. By selecting the appropriate equipment for each step—manual lathes for basic parts, automatic lathes for medium-precision parts, and CNC machining for highly complex components—we ensure efficiency and cost-effectiveness throughout the production process.

By effectively combining manual and automated operations, and leveraging centralized procurement of standard components, we ensure that each step of the machining process is both economical and precise. This approach not only helps us reduce overall production costs by 5%-15%, but also allows us to deliver high-quality, customized rifle scope products for high-end markets and professional users.

| How FORESEEN OPTICS Process Design Helps Reduce Costs

Optimizing process design has a direct impact on improving production efficiency, ensuring product quality, and controlling manufacturing costs. FORESEEN OPTICS continuously enhances the processes of optical fabrication, machining, and assembly to achieve effective coordination and improvement in rifle scope manufacturing.

1. Optimization of Optical Fabrication

Optical fabrication is a crucial part of rifle scope production, directly affecting the optical performance and user experience of the final product.

Optimization of Lens Cutting Paths

In lens processing, FORESEEN OPTICS precisely designs the raw material cutting paths to minimize waste and ensure cutting accuracy. By using advanced optical cutting equipment and optimal cutting path planning, we maximize material utilization while maintaining high optical performance, thereby reducing waste caused by cutting errors.

Lens Grinding Process Optimization

The largest loss in optical lens fabrication often occurs due to over-dimensioning in raw material design. For instance, a 50mm diameter rifle scope lens traditionally requires a blank of 54-55mm, which significantly increases costs, especially for high-grade HD or ED glass. We use advanced CNC lens processing technology to machine glass blanks directly into standard pre-formed lenses, ready for polishing. During the polishing phase, we use various polishing processes to ensure the smoothness of the lens surface.

By selecting the appropriate polishing process according to lens type and aperture requirements, we can shorten polishing time and maintain a high-quality finish. This optimized strategy not only speeds up lens production but also ensures the optical quality necessary for the performance of the final product.

- Optimization of Machining Process

Optimizing machining processes is crucial in the production of rifle scope metal components, impacting component strength, accuracy, and production costs.

Material Selection and Path Optimization

For aluminum alloy parts, FORESEEN OPTICS carefully selects appropriate bar or tube diameters to reduce excess material removal and enhance material utilization. By using programming software to plan the machining paths, we minimize non-productive tool movements and redundant machining steps, ultimately reducing machining time and manufacturing costs.

Equipment Selection and Machining Procedure Optimization

Selecting the right equipment is key to maximizing production efficiency and controlling costs. Based on specific component requirements, we choose lower-axis CNC machines to reduce costs, while using multi-axis CNC machines for complex parts to ensure precision. Additionally, the sequence of turning and milling operations is optimized to ensure efficient material removal and superior surface quality for each component.

- Optimization of Assembly Process

The assembly process is the final step in ensuring the overall quality of rifle scopes, directly affecting product consistency and user experience.

Standardization and Modularization of Assembly

FORESEEN OPTICS standardizes the assembly process to reduce variability in manual operations and maintain consistency across steps. We create detailed assembly operation cards to ensure each step is performed in the most efficient way, improving accuracy and speed. Additionally, some assembly steps are modularized to increase efficiency and simplify transitions between operations.

Use of Specialized Fixtures and Tools

During the assembly process, FORESEEN OPTICS uses specially designed fixtures and tools to reduce time spent on part realignment and repositioning, increasing efficiency and lowering rework rates. These fixtures not only ensure the accuracy of key components during assembly but also enable workers to complete complex steps more efficiently.

Quality Inspection and Feedback Mechanism

After assembly, we use automated inspection equipment to improve accuracy and efficiency in quality checks. Inspection data is fed back into the assembly process, allowing us to continuously optimize assembly steps and enhance overall product quality.

Through ongoing optimization of optical fabrication, machining, and assembly processes, FORESEEN OPTICS not only improves production efficiency and yield rates but also reduces material and processing costs. This comprehensive process optimization allows us to provide customers with high-quality rifle scope products at more competitive prices.

| FORESEEN OPTICS’ Extensive Optical Component Library: Cost Analysis of Mature vs. Newly Designed Optical Systems

FORESEEN OPTICS boasts an extensive library of optical components, including both mature optical systems and newly designed solutions. Compared to creating a completely new optical system, using existing mature systems brings significant cost and time advantages. This approach not only reduces R&D expenses but also accelerates product development, ultimately reducing the production cost of rifle scopes. Below is a detailed cost analysis, highlighting several ways to leverage mature optical systems:

1. Direct Utilization of Existing Systems

For mid- to low-end rifle scopes, customers often prioritize stability and cost control. Utilizing existing optical systems avoids unnecessary costs and complexities associated with redesign. For such products, there is no need to create a new system from scratch. Instead, using mature systems ensures stable production, reduces development costs, and allows products to be launched quickly to meet market demands. This approach is particularly suitable for applications where consistent profitability and cost-effectiveness are essential.

2. Fine-Tuning of Similar Systems

Based on meeting 90% of a customer’s optical requirements, FORESEEN OPTICS can enhance the match through fine-tuning—such as optimizing lens coatings or adjusting lens materials. These adjustments can increase the system compatibility from 90% to 98%, while also saving significant development time and cost, typically reducing R&D expenses by 30-40%. For most brand clients, this approach meets market demands while allowing faster product launches at a competitive price.

3. Partial Use of Mature Optical Systems

FORESEEN OPTICS can also leverage parts of mature optical systems, such as the eyepiece system, image relay system, or objective lens system. This partial reuse method can reduce upfront development costs by 30-50%, as it eliminates the need for a complete redesign and testing of the entire system. Additionally, during mass production, the overall system cost may be reduced by about 10%. This modular design approach ensures an efficient and economical development process.

4. Optical Design Simulation and Batch Testing

During development, we use optical design simulations and batch testing of existing lenses to explore optimization opportunities. When the customer’s core optical parameters allow, we use simulations to determine the possibility of reusing existing lenses. There is approximately a 30% chance that one or two lenses can be directly reused—most commonly in the objective or image relay systems. This approach significantly reduces the core costs of the final product without compromising optical performance.

Overall Advantages of Utilizing Mature Systems

Using mature systems not only reduces development and production costs but also shortens the development cycle, which is crucial for bringing new rifle scopes to market quickly. FORESEEN OPTICS has accumulated 30 years of experience in OEM and ODM for rifle scopes, building a complete library of optical systems across high, mid, and low-end products. This enables us to help new brands quickly establish a product portfolio and support long-term partners in continuously launching cost-effective new products, maintaining competitiveness in the market.

The extensive optical component library and mature system advantages at FORESEEN OPTICS allow us to lead in technology development, cost control, and product launch speed. Compared to designing a completely new optical system, the use of mature systems offers a fast and reliable way for customers to meet market demands, reduce product pricing, and enhance competitiveness.