Product Cases

| FORESEEN OPTICS Custom Development: Cost-Effective Rifle Scope Solution for Assault Rifles

At an international trade show, our team at FORESEEN OPTICS met with a Turkish firearms manufacturer. They were looking to develop a 1-6X28 rifle scope tailored for their assault rifles, specifically for use by security personnel. After initial discussions, the client provided a few key requirements:

- Cost Control: The overall budget was limited, so the scope needed to be designed with a strong focus on cost-effectiveness.

- Imaging Requirements: High clarity was required at the center of the image, while edge resolution wasn’t a priority.

- Shock Resistance: The scope needed to meet the shock resistance requirements of an assault rifle, ensuring reliable performance in harsh environments.

Solution Development:

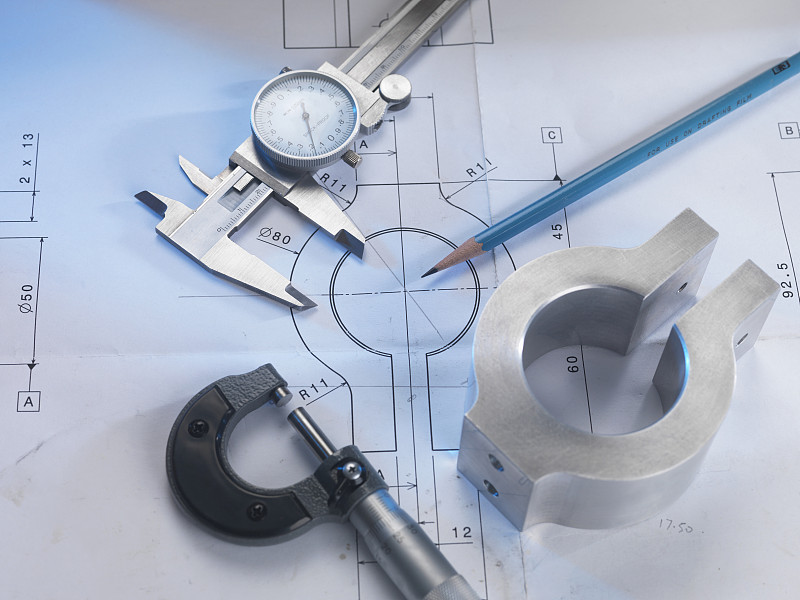

After reviewing the client’s requirements, FORESEEN OPTICS’ engineering team proposed a cost-efficient solution by focusing the budget on critical areas like material selection and manufacturing techniques:

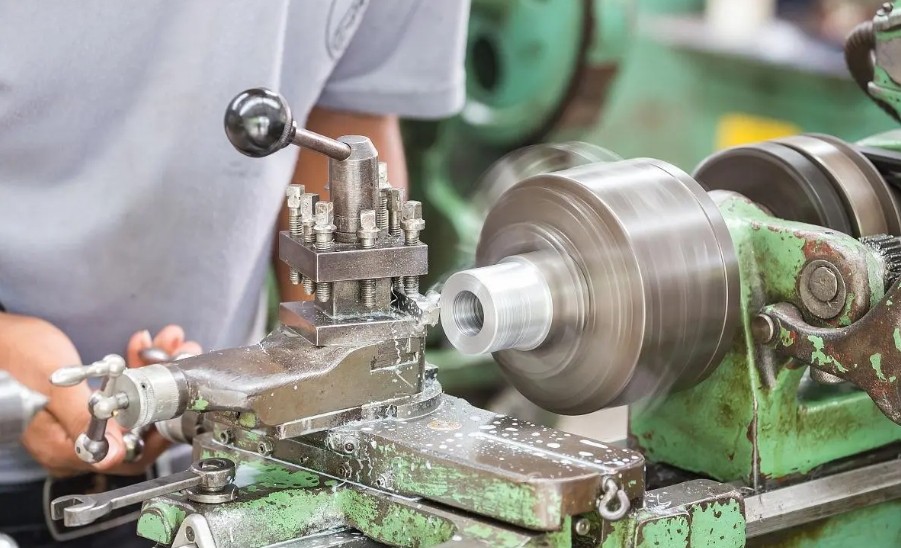

- Integrated Aluminum Alloy Body: Using multi-axis CNC machining and T6-treated aluminum alloy, we thickened the tube walls to increase structural stability and shock resistance, ensuring the scope could withstand heavy impacts.

- Optical Design: We selected proven HD optical lenses and optimized the coating process, prioritizing the enhancement of the scope’s central resolution for crystal-clear images.

- Streamlined Features: To keep costs low, unnecessary high-end features were omitted, maintaining simple yet effective aiming and adjustment functions.

Prototype Design and Client Feedback:

Once the initial prototype was completed, the Turkish client conducted initial testing and provided the following feedback:

- Adjustment Knobs: The knob resistance was too stiff, which affected quick adjustments during urgent scenarios.

- Weight: While the shock resistance was satisfactory, the client requested further weight reduction for easier handling during extended use.

Second Round of Optimizations:

In response to this feedback, our team implemented the following improvements:

- Adjustment Knob Redesign: We replaced the internal damping system, resulting in smoother and more responsive knob adjustments.

- Weight Reduction: By optimizing the CNC machining process and removing unnecessary material while maintaining strength, we successfully reduced the scope’s overall weight.

Final Production and Continuous Optimization:

The client was extremely satisfied with the revised prototype, and the product moved into full-scale production. Throughout the manufacturing process, we further optimized production techniques, which improved material utilization by 3%, reducing waste. We passed these cost savings directly to the client, helping them reduce overall production expenses.

One year after production, the customized scope has performed exceptionally well in the market, generating $200,000 in annual sales, far exceeding the client’s initial expectations. The client expressed their satisfaction with FORESEEN OPTICS’ expertise and optimization efforts, and they have indicated plans to continue collaborating on future product developments.

Collaboration Summary:

- Cost Optimization: We focused the budget on key components and manufacturing techniques, ensuring high performance while controlling costs.

- Iterative Improvement: Through multiple rounds of feedback and refinement, we ensured that the final product met the client’s practical needs.

- Process Enhancements: Ongoing improvements to production techniques lowered costs, allowing us to pass savings on to the client, boosting their product’s competitiveness in the market.

| FORESEEN’s Successful Development and Optimization of an Entry-Level 3-9X42 Rifle Scope

In collaboration with a client from the Middle East, FORESEEN OPTICS once again demonstrated its exceptional custom development capabilities. Initially, the client aimed to create a 4-16X50 sniper scope targeting the big game hunting market. However, due to their sensitivity to pricing, we worked closely with them through multiple discussions and market analyses. Ultimately, we agreed on an optimized solution, developing an entry-level 3-9X42 rifle scope that perfectly balanced cost and performance while meeting the client’s requirements.

1. Initial Requirements and Challenges

The client originally sought a 4-16X50 scope designed for the professional hunting market. During our preliminary analysis, we identified two major challenges:

- Cost Overrun: While the 4-16X50 design was powerful, its high cost exceeded the client’s budget. Moreover, the product required a lifespan capable of handling 5,000 rounds, making it difficult to control overall production costs.

- Market Demand Analysis: After multiple discussions, we realized that the primary target market—big game hunters—did not require high magnification. Instead, they prioritized practicality and durability.

2. Solution Development

After extensive discussions with the client, FORESEEN OPTICS proposed shifting the focus to a more practical and cost-effective 3-9X42 design. This entry-level scope provided sufficient magnification for hunting scenarios while significantly reducing production costs. Key optimizations included:

- Cost Control: By eliminating unnecessary high-end features like zero-stop, 9-level illumination, and precision zoom cam design, we concentrated resources on material selection and durability. The thicker tube walls improved durability and ensured the scope could withstand 5,000 rounds, all while maintaining structural integrity.

- Optical and Reticle Optimization: We selected a cost-effective, proven optical system and adjusted the coating to ensure clear center resolution. For the reticle, we modified the tactical design to a simpler hunting reticle, which provided reliable windage and ballistic compensation. Additionally, we replaced 9-level illumination with a more cost-efficient 6-level design and used capped turrets to maintain waterproofing without adding complexity.

- Durability Guarantee: We optimized the shock resistance to ensure the scope could handle long-term use in rugged environments while maintaining its 5,000-round lifespan.

3. Optimizations and Client Feedback

- 50% Cost Reduction: Through these adjustments, we successfully reduced the product cost by almost 50%, bringing it in line with the client’s budget.

- Successful Prototype Testing: The client conducted thorough field testing of the 3-9X42 prototype and found that the scope performed consistently, with reliable durability. It was particularly effective for hunting large game at lower magnifications.

4. Successful Mass Production and Repeat Orders

The client was highly satisfied with the initial batch of samples and has since placed cumulative orders for over 5,000 units. By optimizing our production process and increasing material utilization, we improved the yield rate from 98% to 99.3%, further enhancing the product’s market competitiveness.

5. Follow-up Collaboration: 4X32 Entry-Level Scope

The client later requested the development of an even more affordable 4X32 entry-level scope to cater to budget-conscious consumers. In this project, we continued to emphasize cost control and process optimization, ensuring that the product maintained stability and reliability despite its lower price point. To date, this scope has had no quality issues, and the client has expressed complete satisfaction, indicating plans for continued collaboration with FORESEEN OPTICS.

Conclusion

This project highlighted FORESEEN OPTICS’ expertise in custom development and cost optimization. Through precise market analysis, streamlined production, and enhanced material utilization, we delivered a high-value product solution that balanced affordability with reliability. This collaboration not only boosted the client’s competitiveness but also solidified FORESEEN OPTICS’ position as an industry leader.

| High-Precision Tactical Rifle Scope Development Journey: Collaborating with a Major Brand

1. Project Background and Client Communication

A renowned international brand approached FORESEEN OPTICS to collaborate on the development of two high-end, long-range tactical rifle scopes: 3-18X50 and 5-30X56. These scopes were specifically designed for military and advanced shooting enthusiasts, with a strong focus on precision and durability.

At the start of the project, we held a detailed video conference. Due to confidentiality, the client did not disclose the firearm platform, but they provided clear expectations for the product’s performance. Their primary concerns were:

- High-precision windage and ballistic compensation adjustments, ensuring stable performance under extreme conditions.

- 99% light transmission, to ensure outstanding image clarity even in low-light environments.

- The product must remain fog-free for 5 years, even under extreme weather conditions.

2. Engineering Team Discussions and Initial Proposal

Following the video meeting, we organized a detailed internal discussion with our optical, coating, and mechanical engineers to devise an initial proposal:

- Sealing and Stability: To ensure the product’s optical quality remained stable over five years, we applied a special military-grade sealing technology, significantly enhancing the scope’s sealing and preventing internal optical elements from aging.

- Optical Design: We implemented a complex 14-lens design combined with 3 groups of ED (Extra-low Dispersion) lenses, ensuring clarity and color accuracy. For coating, we used a 24-layer coating technology, with lenses and coating materials sourced from premium suppliers in Japan, achieving the desired light transmission.

- Mechanical Structure: All internal adjustment components utilized German honing technology, ensuring adjustment precision to 0.001mm. We also performed durability and shock-resistance testing on the adjustment knobs, ensuring long-term stability.

3. Initial Prototype Testing and Client Feedback

Once the initial prototypes were produced, we conducted three internal tests:

- Shock Test: Simulated high-intensity impact during shooting to ensure the scope maintained its precision.

- Deep Waterproof Test: Assessed the scope’s sealing performance in extreme wet conditions.

- Temperature Environment Test: Evaluated the optical and mechanical stability under extreme high and low temperatures.

During these tests, we made minor adjustments to improve performance and then sent the prototypes to the client’s laboratory for validation. The client provided the following feedback:

- Color temperature was slightly blue, and they wanted a more neutral image.

- Knob resistance became too light at high temperatures, raising concerns about operational stability.

- Reticle markings at high magnification showed slight imperfections, which needed improvement.

4. Second Round of Design Optimization

Based on the client’s feedback, we proceeded with the second round of optimizations:

- Coating system redesign: We adjusted both the materials and thickness of the coating layers, successfully correcting the blue tint and achieving more natural color reproduction.

- Knob structure improvement: To address the resistance issue at high temperatures, we switched to a lubricant with a broader temperature threshold, ensuring consistent damping even in extreme heat.

- Reticle upgrade: We replaced the reticle supplier with a more reliable manufacturer, ensuring that all markings remained flawless, even at high magnification.

These improvements resulted in a 3% cost increase, but the client appreciated the enhanced quality and accepted the changes.

5. Final Approval and Small Batch Production

After the second round of adjustments, the client’s laboratory approved the new prototypes, confirming that they met all performance standards. The client then placed an order for 100 units, and we promptly began production. During this phase, the client’s engineers visited our factory, providing valuable suggestions for optimizing the production process. As a result, we improved our assembly efficiency by 7%, while also resolving issues with dust on the reticle.

6. Further Collaboration and Results

Upon successful completion of the initial 100-unit trial order, the client expressed high satisfaction with the products. The 3-18X50 scope became a standout in their mid-to-high-end series, with sales consistently increasing. Additionally, the client expanded the collaboration by adding the 5-30X56 model to their lineup. They are now considering moving more of their U.S.-based scope production to FORESEEN OPTICS, further expanding our partnership.

Conclusion

This collaboration demonstrated FORESEEN OPTICS’ expertise in high-precision optical design, complex coating techniques, and intricate mechanical engineering. Through continuous optimization and improvements, we met the client’s stringent requirements while also increasing production efficiency, laying a solid foundation for future projects.

| FORESEEN’s Quick Response Helps Client Win a Competitive Bid

A Southeast Asian bidding company recently secured an opportunity to submit a proposal for a thermal imaging scope. They provided us with their specifications document, and after analyzing it, we found that their requested parameters closely matched one of our existing thermal scope models. However, a few key adjustments were required:

- Local Language Support: The client requested that the scope’s user interface be available in the local language.

- Reticle Style: The reticle design required by the bid specifications was different from what we currently offer.

- Weight Optimization: The bid specified that the product needed to be lighter than our existing models.

We promptly arranged a video call with the client and explained the following solutions:

- Language Version: Through a simple software upgrade, we could implement the client’s required local language support.

- Reticle: Although the reticle couldn’t be changed immediately for the bid, we assured them that a customized reticle design would be implemented in the final production units.

- Weight Reduction: To meet the weight requirements, we proposed using CNC machining to manufacture the scope housing with lightweight magnesium alloy. Although this would slightly increase production costs, it would fully meet the bid requirements, and the cost increase could be absorbed in future mass production.

Satisfied with our proposed solutions, the client provided the required bid adjustment documents and signed the collaboration agreement the same day. Thanks to FORESEEN OPTICS’ rapid response and flexible solutions, the client successfully won the competitive bid.

| Custom Case Study: FORESEEN OPTICS Custom Process for Hunting Scope Rings

Custom Case Study: FORESEEN OPTICS Custom Process for Hunting Scope Rings

Recently, we worked with a U.S.-based brand client to customize a scope ring specifically for hunting purposes. Initially, the client requested a scope ring made of 7075-T6 aluminum alloy with dual-screw locking. However, during further consultation, we performed an in-depth analysis of the client’s specific needs, including the firearm platform, scope tube specifications, and use case, which revealed opportunities for optimization.

The client’s firearm platform was a Remington 700 rifle, primarily used for hunting in North America. The Remington 700 is a classic bolt-action rifle commonly used for medium-range hunting, with moderate recoil. The client initially considered using dual-screw locking rings made of 7075-T6 aluminum alloy, mainly because they believed this material’s high strength would provide maximum stability. However, through our analysis, we discovered that the client’s actual needs did not require such a high-strength material.

Firstly, the recoil from the Remington 700 does not necessitate the use of 7075-T6 aluminum alloy. Considering the client’s main requirements of durability and cost-effectiveness, we recommended 6061-T6 aluminum alloy. This material provides sufficient strength while being lightweight, making it ideal for extended outdoor hunting, and also significantly reducing material costs. Additionally, after evaluating the overall configuration of the rifle and the length of the scope tube, we found that a three-screw locking design would better meet the client’s needs. The three-screw locking offers superior stability during intensive outdoor shooting, ensuring the scope remains in its intended position.

For the height of the scope ring, we opted for medium-high rings to ensure that the client’s 50mm objective lens could achieve the optimal aiming angle after installation. This setup avoids any interference between the objective lens and the barrel while providing sufficient cheek weld for comfort. This configuration not only meets the practical needs of hunting but also ensures comfort for the shooter during extended use.

The final customized solution included 6061-T6 aluminum alloy, a three-screw locking design, and medium-high ring height. This not only met the client’s hunting requirements but also significantly reduced costs, achieving a perfect balance between performance and affordability. The client was very satisfied with this solution and reported that its performance far exceeded expectations during actual use.

Summary

When customizing scope rings for brand clients, FORESEEN OPTICS starts with a detailed consultation to understand the client’s firearm type, scope specifications, usage frequency, and other key information. Based on this information, we provide professional recommendations in four key areas: material selection, locking strength, ring height, and inner diameter. This ensures that the chosen scope ring meets the client’s needs, guaranteeing stability and accuracy during shooting. FORESEEN OPTICS is committed to providing each client with the most suitable scope ring solution based on these factors, delivering the best shooting experience possible.

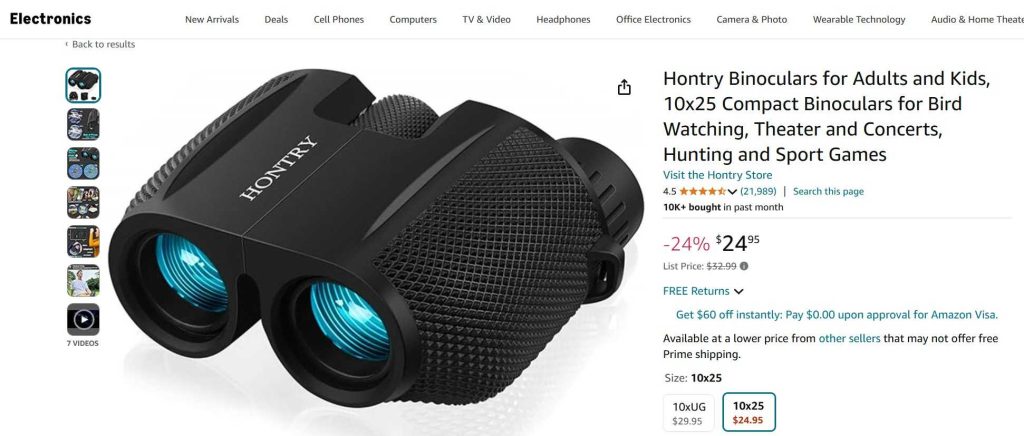

| Customer Case: Kevin’s Binoculars Successfully Launched on Walmart

Kevin, a long-term partner, has consistently performed well on Amazon, earning a strong reputation for sales. Recently, he sought to expand into new channels by introducing these binoculars to Walmart Marketplace.

Background Information

- Customer Name: Kevin

- Operator: Tina

- Product: Best-selling 10×25 binoculars (a product that has been a top seller on Amazon for years)

Challenges

During the initial analysis, Tina identified a key issue:

- The product’s net weight was 0.8 lbs (approx. 363g).

- Walmart’s standard packaging weight was 0.25 lbs, bringing the total billing weight to 1.05 lbs.

- According to Walmart’s WFS (Walmart Fulfillment Services) shipping fee structure, items over 1 lb incur a shipping cost of $4.95 per unit.

- If the total weight could be reduced to ≤ 1 lb, the shipping fee would drop to $3.45 per unit, saving $1.50 per unit.

Tina immediately set out to find a solution for Kevin.

Solution & Implementation

Packaging Optimization:

- Removed non-essential accessories: The integrated eyepiece dust cover was eliminated, as it had minimal impact on the product’s core function.

- Switched to a lighter carrying case: The original Oxford fabric pouch was replaced with a lightweight Neoprene (diving material) case, significantly reducing weight.

Weight Recalculation:

- After optimization, the product’s net weight was successfully reduced from 0.8 lbs (363g) to 0.73 lbs (331g).

- The packaging weight remained 0.25 lbs, bringing the final billing weight to 0.98 lbs, successfully qualifying for Walmart’s ≤ 1 lb shipping fee category.

Final Results

- Shipping cost reduced from $4.95 per unit to $3.45 per unit, saving $1.50 per unit.

- Increased competitiveness: The optimized product became more cost-effective, helping Kevin gain a stronger competitive edge on Walmart Marketplace.

Customer Satisfaction

Kevin highly appreciated Tina’s professional support and efficient solutions, enabling a smooth and successful entry into Walmart Marketplace.

Key Takeaways

Shipping Cost Threshold

According to Walmart WFS shipping policies, exceeding the 1 lb weight threshold significantly increases shipping costs (see chart below).

Product Display and Optimization

The product chosen by Kevin is our highly successful 10×25 binocular, which has been a best-seller on the Amazon platform for many years. It is well-validated in the market and offers strong competitiveness.

Our Standard Process Highlights:

A: Platform Rules Analysis: Quickly review Walmart WFS fee standards to identify the optimal cost-saving opportunities.

B: Efficient Execution: Provide precise optimization plans for packaging and accessories, swiftly addressing customer pain points.

C: Long-Term Strategy: Compare platform fees and logistics strategies to help customers expand across platforms.

Through this case, Kevin successfully launched his product on Walmart’s platform, demonstrating our deep understanding of platform rules and professional cost optimization capabilities. If you have similar needs, our team is always ready to provide support!

Check out some of our best-selling binoculars on Amazon.