Red dot sights, which provide shooters with an easy-to-use and rapid aiming mechanism, have radically changed (the) field of optics.

Overview of the Significance of Red Dot Sights in Modern Optics

Red dot sights, as opposed to conventional iron sights or scope optics, use a single point of light—more precisely, a red dot—projected onto a lens to aid in quick target alignment. Because accurate aim is essential, this capability is particularly significant for objects that move quickly or in poor light. Because the red dot is displayed on a transparent glass that does not obstruct the view of the surroundings, red dot sights have the advantage of allowing both eyes to remain open while in use. This allows the shooter to maintain both focus and awareness of their surroundings.

Despite the fact that some purists contend it diminishes the expertise necessary for traditional marksmanship, this innovation has nevertheless caused a paradigm change in shooting techniques. Dual-eye aiming significantly improves situational awareness, especially in dynamic shooting situations, however it is important to consider any disadvantages. Red dot sights, which are more common in contemporary optics, provide improved accuracy and speed in aiming whether for sport shooting, hunting, or tactical purposes. Because of this development, they are now essential instruments.

It is necessary to recognize, nonetheless, that the efficacy of these tools can vary depending on personal preferences and environmental factors. While many users praise red dot sights’ user-friendly appearance, others might find that traditional scopes are more suited to their particular requirements. Personal specifications must be taken into account when choosing an optical sighting system because of these factors.

What Makes Red Dot Sights So Effective?

Red dot sights, are distinguished by its inherent simplicity, speed, and ability to essentially allow marksmen to quickly and precisely align targets—even in high-stress situations. One of the most important features of a red dot sight is the illuminated dot projected onto a lens. Unlike traditional scopes, which require precise eye alignment and focus, red dot sights do not require a set eye relief distance. In addition to allowing users to focus on the goal, this flexibility allays worries about precise alignment with the optic. Consequently, this speed makes aiming easier, especially when close combat or rapid-fire firing is involved. The subtleties of this technology are still undervalued, though, since many people fail to consider how it might affect performance.

A key component of red dot sights’ effectiveness is their parallax-free design, which is extremely important. Parallax is the apparent change in the reticle’s (or dot’s) position when the shooter’s head moves. Although parallax can make aiming with traditional scopes more difficult, especially when the shooter is not perfectly aligned with the optical device, red dot sights are made so that the dot stays stable on the target even if the shooter’s head (remains) in motion. By reducing the likelihood of misalignment, this design makes shooting faster and easier to understand. Red dot sights are an essential tool for marksmen of all skill levels because to their combination of quick target acquisition, low eye relief needs, and parallax-free design: from casual enthusiasts to military and law enforcement operatives.

Red Dot Sight Manufacturers Overview

The following companies have their own production facilities in nations such the US, Germany, Sweden, and (most significantly.Russia in addition to designing and developing red dot sights. These producers are well known for their emphasis on durability, advanced technology, and accuracy . But this emphasis comes from a deep-seated dedication to excellence and is not just coincidence. These businesses keep their advantage despite the intense competition (because to their creative methods and strict standards).

Aimpoint

Based in Sweden, Aimpoint is a top red dot sight brand worldwide. High-end electronic sights for law enforcement, military, and recreational shooting are its area of expertise.

Strict quality control procedures are followed throughout the production process by Aimpoint, which manufactures its goods in Sweden. Aimpoint, however, withholds certain information regarding their manufacturing facilities.

EOTech

EOTech is well-known for its holographic sights, which are frequently employed in law enforcement and military applications.

The United States state of Michigan is home to EOTech’s manufacturing plant. High-quality control and performance standards are ensured by their in-house design, assembly, and testing of red dot sights.

Trijicon

Trijicon is recognized for (its) high-end optical products (which include) red dot sights that have gained popularity among military, law enforcement, and hunting applications.

Trijicon manufactures all (of its) red dot sights in Michigan, USA; however, the company emphasizes precision craftsmanship and durability in all their optical products. This commitment is evident (because) it ensures that each sight meets rigorous standards. Although some may question the necessity of such high quality, the demand for reliability in critical applications cannot be overstated.

Leupold

Leupold has long been a leading manufacturer (and purveyor) of optical equipment, known for its durable and precise sights (which are favored by many).

Leupold’s production facilities are situated in Oregon, USA; all their products (such as red dot sights) are manufactured in the USA, because of stringent quality control processes. However, some critics argue that this focus on domestic production limits innovation. Although Leupold has maintained a strong reputation, the question remains whether it can adapt to changing market demands.

Holosun

Holosun has rapidly acquired market share, primarily due to its high-performance and cost-effective red dot sights.

Holosun’s production facilities are situated in China (2), where they manufacture red dot sights. However, this company invests heavily in research and development; therefore, it exports products globally. Although the origin of manufacturing might raise concerns, the quality remains uncompromised because of rigorous standards.

FORESEEN OPTICS

FORESEEN OPTICS specializes in the development and production of high-performance, affordable red dot sights. Prior to 2022, the company primarily provided OEM services for large established brands like Bushnell and Vortex, helping them expand their product lines with high-quality optics. Since 2022, however, FORESEEN OPTICS has shifted its focus to designing and producing red dot sights for small to medium-sized brands with more personalized and unique needs. This transition enables these companies to access cutting-edge optics without the burden of in-house manufacturing costs.

FORESEEN OPTICS operates its own manufacturing facilities and ensures strict quality control to meet international standards. The company’s mission is to provide advanced, high-performance red dot sights at competitive prices to a broader range of brands, catering to those seeking more customized solutions, although some might question the ability to maintain quality amidst expansion.

SIG Sauer

Production Background: SIG Sauer (a prominent brand) in the firearms industry produces firearms and optical equipment, including red dot sights.

Public Information: SIG Sauer’s manufacturing facilities are located in both the USA and Germany (however, some parts are outsourced to other regions). Despite this (and other challenges), SIG Sauer maintains high standards for precision and durability (because it is crucial for their reputation).

KOBRA Optics (Russia)

KOBRA Optics (a prominent Russian manufacturer) specializes in military-grade red dot sights and optics.

KOBRA Optics manufactures red dot sights in Russia, focusing on tactical applications and high-precision optics; however, their products are primarily used by military and law enforcement agencies within Russia and abroad. Although the company has garnered a reputation for quality, it faces challenges because of increasing competition in the optics market. This evolution is critical for maintaining its status among global manufacturers.

Key Manufacturing Steps of Red Dot Sights

This section refers to the production process document of FORESEEEN OPTICS.

- Initial Material Procurement

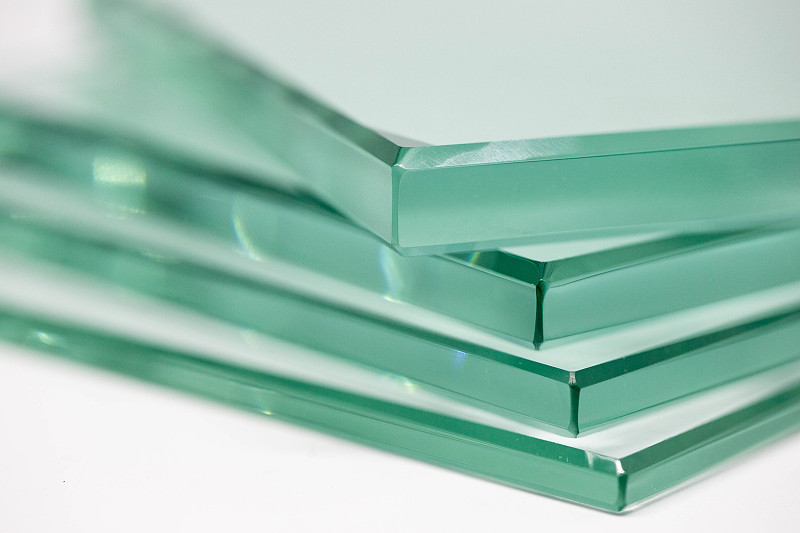

The meticulous selection of raw materials is the first step in the creation of red dot sights. We purchase premium optical glass, aluminum alloys, and other essential parts from vendors who are well-known throughout the world. To make sure they satisfy industry requirements, all materials go through extensive quality testing.

- Incoming Quality Control

Incoming quality checks are performed on materials prior to their entry into the production line. In order to make sure the materials fulfill production requirements, this stage focuses on analyzing their dimensions, surface flaws, and optical characteristics. The supplier will get any materials that do not match the requirements.

- The Importance of CNC Machining Technology

In order to produce red dot sights, precise CNC (Computer Numerical Control) machining is essential. We can guarantee that each part’s dimensions are strictly regulated with very small tolerances thanks to this technology. This is necessary for both the overall structural integrity of the sight and the exact alignment of optical components.

- The Importance of Cleanliness and Precision

The effectiveness of red dot sights is directly impacted by the cleanliness of optical components. We strictly regulate the air and environmental cleanliness at every stage of production to keep dust and oil from contaminating the optical system. Furthermore, each component’s accuracy needs to be guaranteed, particularly during alignment and assembly.

- Core Component Assembly

All machined pieces are meticulously placed at the core component assembly stage. This covers the optical adjustment mechanisms, electronic modules, and lenses. Every component is independently inspected to guarantee appropriate fit and performance.

- Testing and Calibration

We execute a number of tests on the sight after it has been assembled, including optical performance testing (field of view, brightness uniformity, etc.) and electronic function tests (sensitivity, red dot brightness adjustment, etc.). To make sure the red dot sight can survive challenging weather conditions, we also conduct shock resistance testing.

- Final Assembly and Integration

The final assembly and integration procedure starts once every part and function has been verified to be in working order. At this point, integrating all the parts flawlessly is the aim in order to guarantee the integrity, robustness, and operation of the sight.

- Optical and Electronic Calibration

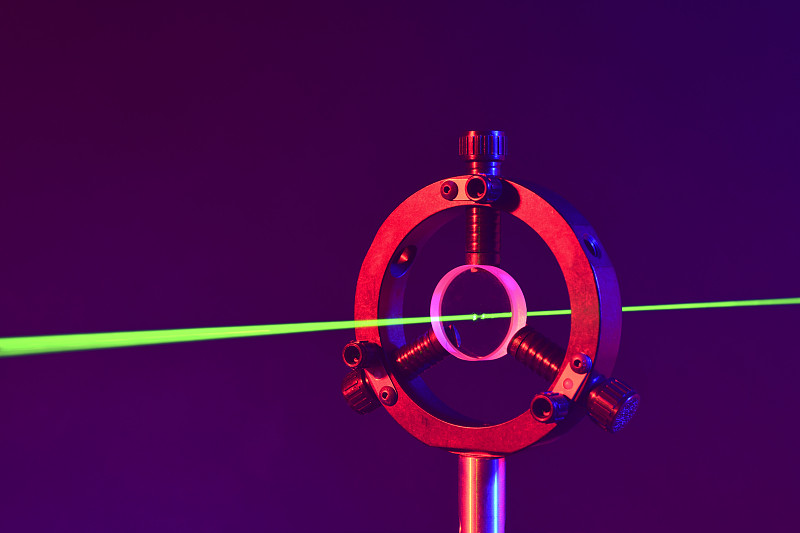

To guarantee that the red dot is precisely aligned, the optical and electronic systems are finalized through calibration. We guarantee the sight’s accuracy and functionality during real-world operation by carefully aligning and adjusting the laser.

- Post-Production Quality Checks

Following final assembly, we carry out a thorough quality check. To guarantee that its performance stays consistent under a range of environmental circumstances, every product is put through a battery of tests, including those for aging, shock resistance, humidity, and other factors.

- OEM Order Packaging and International Shipping

We package the items in accordance with the particular requirements of OEM clients once they have passed all quality inspections. While taking portability into account, the packaging design guarantees the product’s safety. Lastly, in order to guarantee prompt delivery to our customers, all products are transported worldwide via international logistics.

Red dot sight manufacturing is an extremely accurate procedure that calls for fine craftsmanship. Every stage, from the production of lenses to the installation of electronic components, needs to be carried out with extreme precision. Even the slightest deviation can affect the final optical performance, particularly when it comes to lens coatings and reflectance control. Strict quality control procedures assist the production process to guarantee that every red dot sight satisfies strict requirements, ensuring dependability and performance in a range of scenarios. In this regard, research from FORESEEN OPTICS suggests that they devote considerable personnel and time into precision control during lens assembly, maximizing the optical performance of each lens and enhancing the overall quality and stability of the product.

The Future of Red Dot Sight Technology

Upcoming Trends in Optics and Red Dot Sights

Red dot sight technology is developing toward more intelligent features, more endurance, and greater precision. Future red dot sights might incorporate additional digital displays, environmental flexibility, and improved smart device interoperability as optical technology develops. While adaptive brightness controls will guarantee visibility in a range of lighting conditions, more efficient battery technologies will increase usage times. Furthermore, it is anticipated that red dot sights will become even more user-friendly for tactical and recreational use by becoming smaller and lighter without sacrificing performance.

The Importance of Human Craftsmanship and Technology Integration

Human skill is still essential in the production of red dot sights, even if automation is a significant part of many production processes. With years of experience and meticulous attention to detail, skilled artisans are able to spot and fix minor flaws in the production process. Further evidence that manual assembly and inspection are particularly important throughout the optical system calibration stages comes from research conducted by FORESEEN OPTICS. Specifically, human experience guarantees that every red dot sight reaches the maximum level of accuracy during final performance testing and fine-tuning. Furthermore, the production of red dot sights has achieved previously unheard-of levels of precision and quality because to the fusion of sophisticated automation and human expertise.

Innovations on the Horizon

Red dot sight technology is developing toward more intelligent features, more endurance, and greater precision. Future red dot sights might incorporate more digital displays, environmental flexibility, and improved optical technology as it develops. Red dot sights’ future will prioritize the enhancement of human-machine interfaces in addition to more conventional targeting features. Red dot sights, for instance, might be able to communicate with other devices via wireless technology, allowing for more accurate setting and adjustments. Future red dot sights may have ultra-precise optical focusing systems thanks to developments in laser and nanotechnology, which would improve the shooter’s ability to aim precisely even in challenging circumstances. These developments will enhance the use of red dot sights in a variety of fields, including sports shooting and military applications.