The primary function of a scope ring is to ensure that a rifle scope remains absolutely stable after installation, allowing each shot to hit the target with precision while providing the shooter with a comfortable cheek weld during aiming. Choosing the right scope ring isn’t just about securing the scope; it also needs to accommodate the varied environmental conditions encountered during shooting, ensuring consistent accuracy under all circumstances. Additionally, the design of the scope ring must cater to the shooter’s personal needs, such as cheek weld, ring height, and aiming angle.

Due to these diverse requirements, there are many different types of scope rings on the market. Each rifle scope can often be adapted to multiple firearm platforms, which provides flexibility for shooters to easily switch between rifles without the need to frequently re-zero the scope. This flexibility is especially important for those who use multiple firearms and want to maintain a consistent aiming baseline.

As a professional scope ring manufacturer, FORESEEN OPTICS provides customized solutions for each brand client based on their unique requirements. During our customization process, we consider four key aspects to ensure that our clients achieve the best shooting experience:

1. Consultation on Firearm Compatibility

The first step in customization is to have a detailed consultation with the client to understand the specific type of firearm, scope specifications, and usage frequency. For example, is the client primarily using the firearm for hunting, competition, or tactical purposes? Information such as the barrel profile, the size of the objective lens, and the diameter of the scope tube are crucial factors in determining the appropriate ring configuration. Based on this information, we provide tailored recommendations regarding material, locking strength, ring height, and inner diameter specifications.

2. Material Selection

The material selection directly affects the durability, weight, impact resistance, and recoil handling capability of the scope ring:

- 6061-T5/T6 Aluminum Alloy: Suitable for moderate recoil and standard use, it offers good strength and corrosion resistance. It is a lightweight and cost-effective choice.

- 6063-T6 Aluminum Alloy: Ideal for lightweight rifles or less frequent use. Its high toughness makes it suitable for small-caliber rifles, but it is not strong enough for high-recoil firearms.

- 7075-T6 Aluminum Alloy: Suitable for rifles with high recoil and frequent use. This aluminum alloy offers exceptional strength and durability but comes at a higher price, primarily used for high-end applications.

- Steel: Steel rings offer the highest strength, making them ideal for large-caliber rifles and high-recoil environments. Although heavier, their stability is crucial for long-range precision shooting.

- Carbon Fiber: Carbon fiber is an innovative material that combines high strength with minimal weight, making it ideal for users who require lightweight gear. It not only reduces overall weight but also improves shock resistance, suitable for long-duration and precision shooting.

3. Locking Strength of Scope Rings

Locking strength is critical to ensuring the stability of the scope, particularly during high-frequency shooting and in situations involving significant recoil:

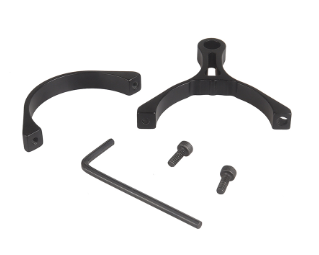

- Single-Screw Locking: Suitable for small-caliber rifles and lightweight scopes. It is lightweight and easy to install but has relatively lower locking strength.

- Dual-Screw Locking: Provides higher stability and locking strength, making it a versatile and stable option for medium-caliber rifles.

- Triple-Screw Locking: Used for large-caliber, high-recoil rifles that require maximum stability to ensure the scope does not shift during intense shooting.

The locking mechanism should be selected based on the relationship between the scope tube and the mounting position, as well as the recoil characteristics of the firearm, to ensure the scope remains accurate in any condition.

4. Scope Ring Height

The height of the scope ring should be determined based on the size of the objective lens, barrel profile, and the shooter’s aiming habits:

- 40mm Objective Lens or Smaller: Typically suitable for low rings, regardless of the specific barrel profile. The smaller size of the objective lens means it usually clears the barrel without issue.

- 50mm Objective Lens: For barrels with a profile smaller than #5, low rings can be used, whereas larger barrel profiles require medium or medium-high rings.

- 56mm Objective Lens: Barrels with profiles smaller than #5 typically require medium rings, while Sendero profiles or barrels larger than #7 will need medium-high or high rings.

- Consideration for Built-in Cant Base: If using a base with built-in elevation (e.g., 20 MOA), the angle needs to be calculated to ensure sufficient clearance between the scope and the barrel.

5. Inner Diameter of Scope Rings

The inner diameter is determined by the scope tube size, ensuring a secure installation without compromising accuracy:

- 1-Inch Tube: Used for basic scopes and general hunting rifles.

- 30mm Tube: The most common size, suitable for most mid-to-high-end rifle scopes, offering good optical performance and stability.

- 34mm Tube: Used for high-end scopes, providing greater adjustment range and suitable for long-range shooting and tactical applications.

- 36mm Tube: Designed for scopes requiring a larger adjustment range and higher precision, ideal for high-end tactical and long-range precision shooting.

Summary

When customizing scope rings for brand clients, FORESEEN OPTICS conducts an in-depth consultation to understand the client’s specific needs and provides targeted recommendations with diverse options. From materials and locking strength to ring height and inner diameter, we tailor the best solution for our clients, ensuring that they achieve optimal stability, precision, and comfort in any shooting scenario. We are committed to delivering superior shooting experiences through our professional services and high-quality products.